What are Lashing Bands?

Container lashing bands are specialized straps designed to secure and stabilize cargo during transport. Made from durable materials such as steel, polyester, or other composites, these bands are crucial in preventing the movement of containers, especially during sea, air, or road transit.

The necessity of container lashing in the shipping and transport industry is fundamental. With thousands of containers being transported daily, ensuring their stability is not just about preventing damage to the goods inside. It’s also about ensuring the safety of the transportation medium, whether it’s a ship or a truck, and the personnel involved. Properly lashed containers maintain balance and weight distribution, reducing the risk of accidents or loss during transport. In a sector where timely and safe delivery is crucial, container lashing bands are essential in achieving that objective.

Different Types Of Lashing Bands

Lashing bands are integral to the transportation and shipping industry, providing much-needed stability and security for cargo during transit. Different types of lashing bands are employed depending on the nature of the cargo, its weight, and the mode of transportation.

The appropriate method and material hinges on several factors, including cargo nature, environmental challenges, transportation mode, and specific safety prerequisites.

Steel Lashing Bands: Steel bands, predominantly made from high-tensile steel, stand out for their unparalleled strength and resilience. They are a frequent choice when transporting heavy cargo, especially across oceans where the prevention of cargo shift is paramount.

Their wear and tear resistance and excellent load retention capabilities make them ideal for situations that demand heightened security. However, it’s essential to note that these bands might be susceptible to corrosion without proper coating or treatment and are relatively heavier than their counterparts.

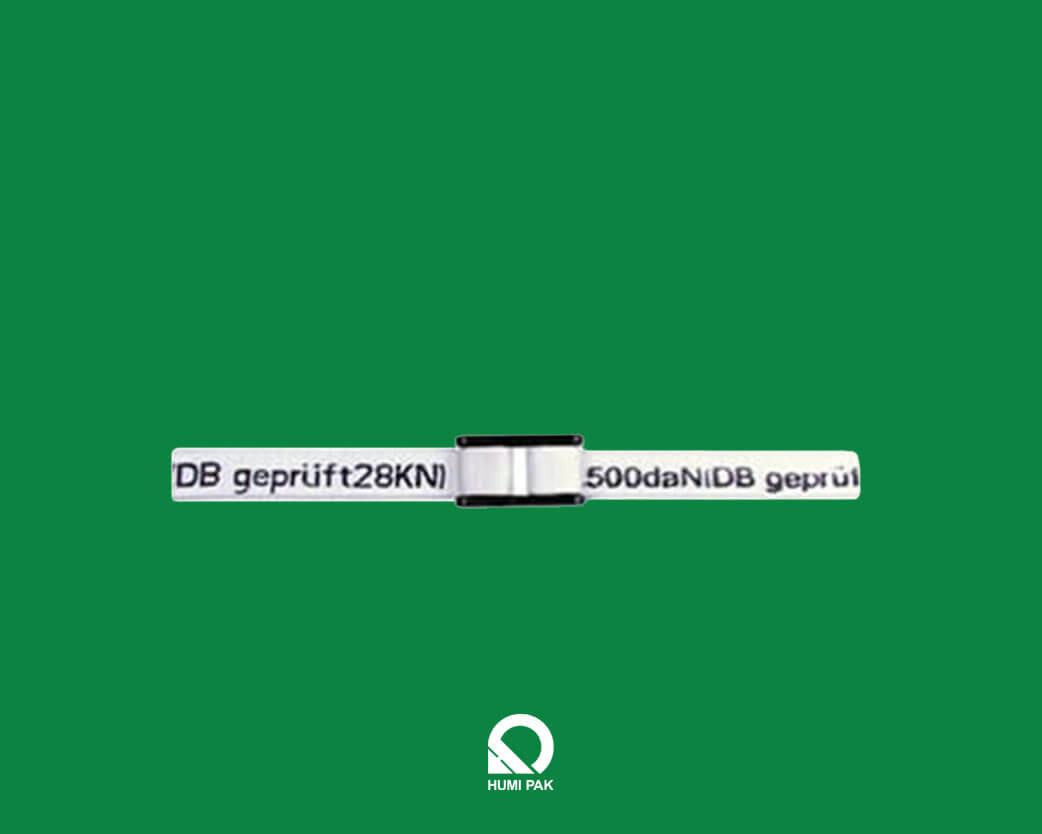

Polyester Lashing bands: Constructed from woven polyester fibres, these bands offer a harmonious blend of strength and flexibility. They are ideal for securing palletized goods, boxes, and crates, especially during road and rail transport.

One of their distinguishing features is their resistance to UV radiation and inclement weather conditions. Furthermore, being lightweight, they pose minimal risk of causing damage to the surface of goods. Despite their versatility, their tensile strength might not match steel’s, making them less suitable for extremely hefty or oversized cargo.

Composite Straps: The composite method employs a mix of materials, often combining polyester fibres with polymer coatings. These bands cater to various applications, from light cargo to medium-heavy loads. Their chief advantage lies in striking a balance: they offer both strength and adaptability.

This dual nature makes them resistant to environmental challenges and ensures they can be tailored to cater to distinct cargo specifications. However, the downside often revolves around cost—being more expensive than their single-material counterparts—and not quite reaching the extreme strength of steel variants.

Corded and Woven Methods: Braiding or interlacing multiple strands, usually of polyester or similar synthetic materials, results in corded or woven straps. These are especially suited for lighter cargo, bales, and pallets. They excel in shock absorption, adapting seamlessly to the cargo’s contour, and their user-friendly nature makes them a preferred choice for many. However, their tensile strength might not be apt for heavier or bulkier loads that require significant tension.

Material Properties and Considerations for Cargo Securing

When choosing the appropriate materials for securing cargo, it’s vital to understand the inherent properties of these materials and the external factors that may influence their performance. When selecting materials for cargo securing, understanding and evaluating these properties about the cargo’s nature, transport mode, and environmental exposure is essential. The right material ensures the cargo’s safety and optimises the transport process’s efficiency and reliability.

Strength and Tensile Properties: The primary role of any cargo-securing material is to hold the cargo firmly in place, preventing unwanted shifts during transportation. Hence, the material’s strength and tensile properties are paramount.

Tensile strength refers to the maximum amount of tensile (pulling) stress a material can withstand without breaking. Materials with higher tensile strength, such as high-tensile steel, can secure heavier loads without the risk of snapping or failing. Evaluating a material’s strength and tensile properties ensures that it can endure the rigorous demands of cargo transport, especially under dynamic conditions.

Resistance to Environmental Factors: Cargo often traverses through varied environments, exposing securing materials to various external factors. These materials must resist elements like moisture, which can lead to corrosion, especially in metal-based bands.

Similarly, UV resistance becomes crucial for materials like polyester bands, which might be exposed to prolonged sunlight, especially in open transport modes like shipping or flatbed trucking. A material’s ability to resist environmental factors not only prolongs its life but also ensures the consistent safety of the cargo throughout the journey.

Elasticity and Elongation Considerations: Elasticity refers to a material’s ability to return to its original shape after being stretched or deformed. Conversely, elongation indicates how much a material can be stretched from its original length before breaking. These properties are vital, especially when securing cargo that may settle or shift slightly during transport.

For instance, corded or woven straps made from synthetic materials often exhibit a degree of elasticity, allowing them to adapt to the cargo’s contours and movements. However, it is crucial to ensure that the material’s elasticity doesn’t compromise its overall strength. An optimal balance between elasticity and strength ensures the cargo remains secure while accommodating minor shifts or settlements.

Techniques and Tools for Application

Securing cargo effectively requires the right materials, techniques, and tools to ensure optimal safety. The application process is pivotal in determining the overall stability of the transported goods. Cargo securing is a balance between using the right tools, applying effective techniques, and regularly inspecting the setup. Proper application ensures the cargo’s safety and the transport process’s overall efficiency.

Manual Tensioning vs. Automatic Tensioning:

- Manual Tensioning: As the name suggests, this involves manually applying tension to the securing material, typically using hand tools. It offers a hands-on approach, allowing the operator to feel the tension and adjust accordingly. Manual tensioning tools, such as ratchet tie-downs or buckle devices, are widely used for their simplicity and cost-effectiveness.

- Automatic Tensioning: This method employs motorized or pneumatic tools that automatically apply tension to the securing material. Automatic tensioners ensure consistent tension across all securing points, reducing the risk of human error. They are particularly beneficial for larger operations where uniformity and speed are crucial. However, they might be more expensive than manual tools and require regular maintenance.

Lashing Tools and Devices:

- Ratchet Straps: These versatile tools allow easy tensioning and release and are widely used for loads of various sizes.

- Winch Bars and Winches: Primarily used for heavy-duty applications, they can exert significant tension, especially for larger and heavier cargo.

- Corner Protectors: These aren’t tensioning tools per se but play a vital role in preventing the securing material from cutting into the cargo and vice versa.

- Tensioning Bars: Often used with steel bands, they help achieve the desired tension manually.

- Pneumatic Tools: Designed for automatic tensioning, they use compressed air to ensure consistent and optimal tension.

Proper Techniques for Optimal Security

The technique’s precision is paramount in the intricate process of cargo securing. Equally significant as selecting the right tools, the application technique can determine the efficacy of the entire securing process. One foundational principle is the regular inspection of the cargo and its securing materials before and after tensioning. Such assessments and preventative checks help to identify and rectify potential vulnerabilities or issues.

Furthermore, the principle of even distribution is vital. It ensures that tension is uniformly spread across all securing points, thereby upholding the balance and stability of the cargo. Uneven tensioning can lead to dangerous imbalances, compromising the safety of the cargo and the transport vehicle.

However, while ensuring adequate tension, avoiding over-tensioning is equally important. An excess of tension can be counterproductive, posing a risk of damage to the cargo or compromising the integrity of the securing material. Therefore, adherence to recommended tension levels is non-negotiable, ensuring a secure yet non-damaging grip on the cargo.

Lastly, for sizable cargo, the technique of multi-point securing becomes vital. The load’s weight and pressure are dispersed more evenly by anchoring the cargo at various points. This distribution enhances stability and minimizes the risk of creating pivot points that can jeopardize the cargo’s security during transit. Understanding these techniques is foundational to ensuring cargo’s safety, stability, and security throughout its journey.

Safety and Best Practices

Ensuring the safety and integrity of cargo during transit is important, not just for the protection of goods but also to ensure the safety of the transportation crew and the general public. Adhering to a set of best practices is critical in maintaining standards. Understanding the nuances of the materials and techniques used and instilling a culture of safety and vigilance can significantly minimise risks, ensuring that goods reach their destination without incident.

Proper Application and Tensioning: Every securing material has an optimal tension range that provides the most secure grip without causing damage. Proper application involves correctly positioning the securing materials and ensuring they’re tensioned within this optimal range.

Over-tensioning can compromise the cargo’s safety by putting undue stress on the securing material and the cargo itself, while under-tensioning might not hold the cargo securely. Using the correct tools and techniques to achieve the right tension is essential, ensuring stability throughout transportation.

Regular Inspection for Wear and Tear: Like all tools and materials, securing devices are prone to wear and tear, especially given the demanding environments in which they operate. Periodic inspections help identify signs of damage, such as fraying in woven bands, corrosion in steel bands, or any other form of deterioration. Immediate action, such as repair or replacement, should be taken if wear and tear are observed, ensuring the continued effectiveness and safety of the securing materials.

Precautions during Handling and Transportation: Certain precautions should be taken to maintain safety when loading and unloading cargo and during transit. These include ensuring a clear and safe path during loading and unloading, using the right equipment, and following standardized procedures for handling different types of cargo. Additionally, drivers and transportation personnel should be trained to respond appropriately to situations where cargo might shift or become unstable during transit.

Recognizing and Addressing Potential Hazards: Proactively identifying hazards can significantly reduce risks. This involves assessing the cargo’s nature, weight, shape, other characteristics, and the journey’s conditions, such as weather and terrain. Recognizing these factors beforehand allows for better planning and preparation.

For example, knowing that a route involves rough terrains may mean using extra securing points or stronger materials. Training personnel to recognize and address these hazards ensures they’re equipped to make real-time decisions, enhancing overall safety.

Conclusion

Container lashing bands play a critical role in the world of cargo transportation. These bands, vital for securing cargo, ensure the goods’ safety and the infrastructure and personnel involved. As the demands of global trade continue to evolve, the practices and materials used to secure cargo will need to adapt accordingly, underscoring the ongoing relevance and importance of this topic.

Humi Pak offers a wide range of load securement solutions to safeguard goods against damage during transit. We also provide training to ensure optimal use and safety. To learn more about how we can enhance your shipping safety and efficiency, reach out to our packaging engineers and schedule a consultation.