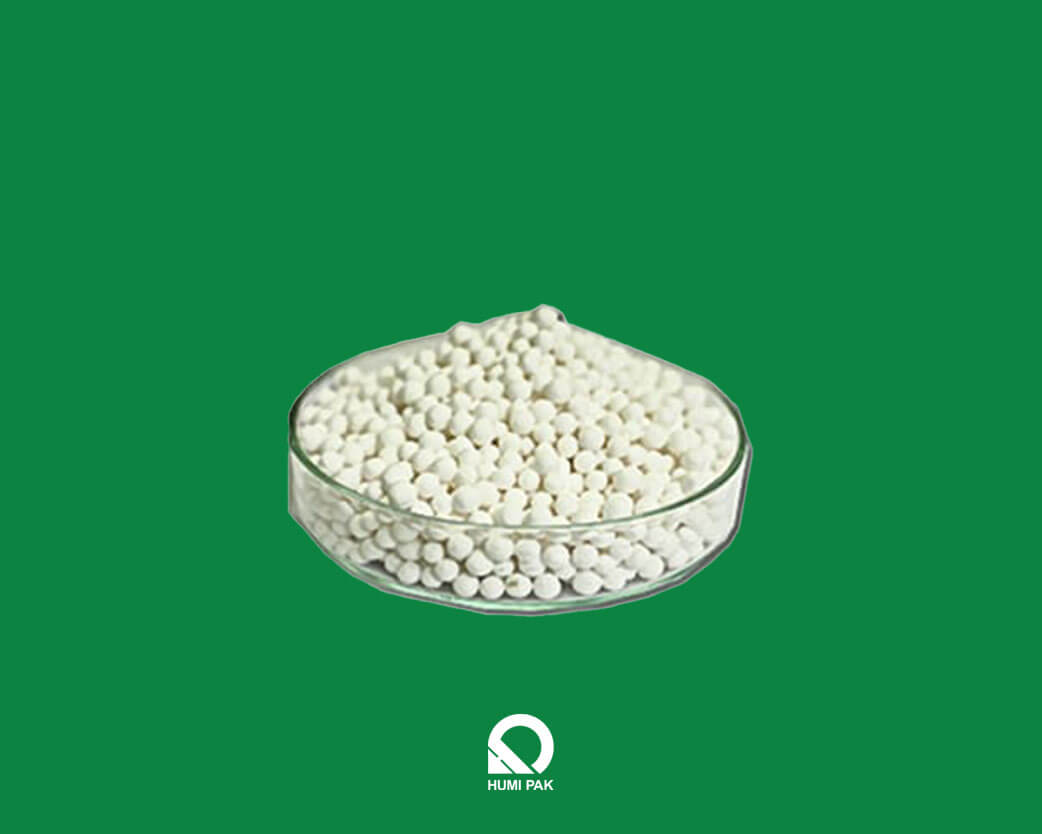

What is Activated Alumina?

Activated alumina, often recognized by its white, spherical appearance, is a form of aluminium oxide (Al₂O₃) that is highly porous and exhibits tremendous surface area. Due to its porosity, it is particularly effective in adsorbing both gases and liquids, making it a material of choice in various industrial applications. Its ability to absorb moisture and other contaminants has found significant utility in areas ranging from water purification to packaging.

Introduction to Activated Alumina

Activated alumina is essentially a form of aluminium oxide (Al₂O₃). Unlike its dense and non-porous counterpart, activated alumina possesses a highly porous structure, which results in an expansive surface area.

This structure, consisting of many microscopic tunnels and pores, renders it a remarkable adsorbent. When examined under a microscope, activated alumina reveals a sponge-like texture, perfect for trapping gases, liquids, and suspended solids.

The manufacturing of activated alumina starts with the hydration of aluminium powder. This hydration process leads to the formation of aluminium hydroxide. Following this, the hydroxide undergoes controlled dehydration at elevated temperatures, typically in a rotary kiln or continuous-belt calciner. This high-temperature dehydration removes bound water from the hydroxide, leading to the formation of the porous aluminium oxide structure that is characteristic of activated alumina.

The specific properties of the activated alumina, such as its pore size and surface area, can be fine-tuned by adjusting factors in the production process. This includes the duration of the calcination, the peak temperature reached, and the rate of temperature increase.

As a result, activated alumina can be custom-produced to meet specific industrial requirements, making it a versatile tool in various applications ranging from gas purification to catalyst support in petrochemical industries.

Properties of Activated Alumina

The combination of activated alumina’s physical and chemical properties makes it versatile in many industrial applications. Its high porosity and surface area enable effective adsorption, while its chemical stability ensures efficiency and safety in various applications.

Physical Properties:

- Porosity: Defined by its high porosity, this material possesses a sponge-like structure filled with numerous tiny pores. This allows it to trap and hold various substances effectively, making it a favourite in adsorption processes. The pore size and distribution can be controlled during production to cater to specific industrial requirements.

- Surface Area: Owing to its nature, it boasts an impressive surface area, often ranging between 200 to 400 m²/g. This extensive coverage plays a pivotal role in its effectiveness as an adsorbent, with a larger area allowing for more efficient adsorption of molecules, such as in water purification or gas separation.

Chemical Properties:

- Reactivity: While generally inert and non-reactive with most chemicals, under certain conditions, especially elevated temperatures or specific substances, it might exhibit some reactivity. For instance, it can be a catalyst or support for select chemical reactions.

- Stability: Its popularity in many applications can be attributed to its chemical stability. It remains unaltered in both acidic and basic environments, ensuring a consistent structure and performance even with varying pH levels. This stability also prevents leaching or the release of harmful substances during purification processes.

Safety and Handling of Activated Alumina

Adhering to guidelines can ensure the safe and environmentally responsible use of activated alumina in packaging applications. Proper storage, handling, and disposal are paramount in maintaining the material’s effectiveness while safeguarding the health of handlers and the environment.

Best Practices for Storage:

- Environment: Store activated alumina in a cool, dry place away from direct sunlight. Excessive heat or moisture can compromise its adsorptive capabilities.

- Sealed Containers: Ensure the material is kept in tightly sealed containers to prevent contamination or premature adsorption of moisture or other gases from the surrounding environment.

- Avoid Mixing: Do not mix old and new batches of activated alumina. This prevents potential inconsistency in adsorption performance.

- Keep Away from Reactive Substances: Store away from chemicals or substances that might react with it, ensuring the material retains its inert nature.

Safety Precautions During Handling:

- Personal Protective Equipment (PPE): While handling activated alumina, wear appropriate PPE, including gloves, safety glasses, and a dust mask, especially when dealing with large quantities or during transfer operations.

- Avoid Inhalation: Though the material is generally safe, it’s essential to avoid inhaling dust. Ensure proper ventilation in the working area.

- Clean Spills Promptly: If any spills occur, clean them immediately using a broom or vacuum to prevent slip hazards.

- Handle with Care: When transferring or pouring activated alumina, do so gently to reduce dust production.

Environmental Considerations:

- Disposal: Used activated alumina should be disposed of according to local regulations. Depending on its usage, it might have adsorbed hazardous or toxic substances, making its disposal critical.

- Recycling: Where possible, consider regenerating or recycling spent activated alumina. Some industries have processes to refresh the material for reuse.

- Water Runoff: Ensure that activated alumina particles do not enter water sources, as they can impact aquatic ecosystems.

- Sustainable Production: Advocacy for and support of energy-efficient production methods that produce minimal waste can help reduce the environmental footprint of activated alumina.

Benefits of Using Activated Alumina

Incorporating activated alumina into packaging solutions offers a comprehensive array of benefits. From ensuring product protection and freshness to providing an economical and efficient solution, its multifunctional properties establish it as a desiccant choice across diverse industries.

Protection Against Humidity and Moisture Damage: Activated alumina is an effective moisture barrier in packaging. Its potent adsorption capabilities ensure that products remain dry and free from the damaging effects of humidity.

This particularly benefits moisture-sensitive items, such as electronics or certain chemicals. Activated alumina ensures product safety and contributes to extended shelf life and reduced risk of malfunction or degradation by effectively trapping moisture and preventing access to packaged items.

Preservation of Product Freshness: The unique structure of activated alumina, characterized by its porosity and expansive surface area, allows it to absorb moisture and other gases. This capability is crucial in preserving the freshness of products, especially consumables like food or pharmaceuticals.

With the aid of activated alumina, packaged foods can retain their original flavours for extended periods, minimizing the chance of them turning stale or spoiling. Furthermore, by maintaining a stable internal environment within the package, activated alumina ensures the product’s overall quality and freshness are preserved.

Prevention of Mold, Mildew, and Other Contaminants: Activated alumina’s ability to regulate the internal environment of a package positions it as a key player in inhibiting the growth of unwanted organisms such as moulds and mildew.

By maintaining a dry atmosphere within the packaging, the conditions become unfavourable for fungal growth, ensuring products remain safe for consumption or use. Beyond just moisture, activated alumina can also trap and immobilize other potential contaminants, further enhancing the safety and purity of the packaged items.

Cost-effectiveness Compared to Other Desiccants: One of the standout attributes of activated alumina is its high adsorption capacity. This means that even smaller quantities can achieve the same drying results as larger quantities of other bulk desiccants. This efficiency translates to tangible cost savings in material procurement.

Moreover, activated alumina’s durability and chemical stability means it retains its adsorptive properties over extended periods, offering a long-lasting solution for packaging needs. In certain scenarios, this desiccant can even be regenerated and reused, cutting down on the continuous costs associated with purchasing and disposing of desiccants.

Key Industries and Applications

Activated alumina’s versatility and efficacy position can be used across various industries. Its adaptability to diverse packaging needs, from safeguarding medications to protecting electronics, underscores its importance in today’s market.

Pharmaceutical Packaging: In the pharmaceutical industry, ensuring the integrity and potency of medications is important. Activated alumina plays a pivotal role in pharmaceutical packaging by maintaining a controlled moisture-free environment. This is crucial as certain medications, especially those in powder or tablet form, are highly sensitive to humidity, which can compromise their efficacy or shelf life.

Moreover, preventing microbial growth, which thrives in moist conditions, is vital to guarantee the safety and purity of pharmaceutical products. By incorporating activated alumina into pharmaceutical packaging, manufacturers can provide extended protection against moisture and contaminants, ensuring drugs retain their intended effectiveness and quality.

Food and Beverage Packaging: Preserving freshness and preventing spoilage are top concerns in the food and beverage industry. Activated alumina, when used in food packaging, addresses these concerns efficiently. It helps maintain the desired dryness level within the package, safeguarding food items from the adverse effects of humidity.

For certain food products, even a slight change in moisture levels can lead to staleness, spoilage, or unwanted microbial growth. Beverages, especially those in powder form like instant coffee or powdered juices, benefit significantly from this protection. With activated alumina’s inclusion, manufacturers can ensure prolonged freshness, taste retention, and overall product quality.

Electronics Packaging: Electronics and their components are inherently vulnerable to damage from moisture, which can cause short circuits, corrosion, or even system failures. When integrated into electronic packaging, activated alumina serves as a protective shield against such damages.

It maintains an optimal dry environment within the package by effectively adsorbing ambient moisture. This is particularly beneficial for sensitive electronic components, semiconductors, or devices for storage or long-distance shipping. By leveraging the moisture-adsorbing capabilities of activated alumina, electronics manufacturers can enhance product longevity and reduce the risk of moisture-induced malfunctions.

Specialized Industrial Packaging: Various industrial applications require specialized packaging solutions to protect goods from contamination, moisture, and other environmental factors. Activated alumina emerges as a reliable ally, whether it’s the packaging of sensitive chemical compounds, machinery parts susceptible to rust, or products that must be stored in a controlled environment for extended periods.

Its high adsorption capacity and chemical stability make it an option for numerous industrial packaging needs; by ensuring a consistent and dry environment within the package, activated alumina aids in preserving product integrity, preventing degradation, and offering a layer of protection against external contaminants.

Conclusion

Activated alumina has established itself as a reliable component in modern packaging solutions. Its ability to effectively control moisture has made it essential in industries that require precise environmental conditions, such as pharmaceuticals, electronics, and food.

With its consistent performance, cost-effectiveness, and versatility, activated alumina offers a practical solution to many of the challenges faced in packaging. Humi Pak offers a premium selection of activated alumina desiccants tailored to your needs. Reach out to us for detailed insights and recommendations.