What is Molecular Sieve?

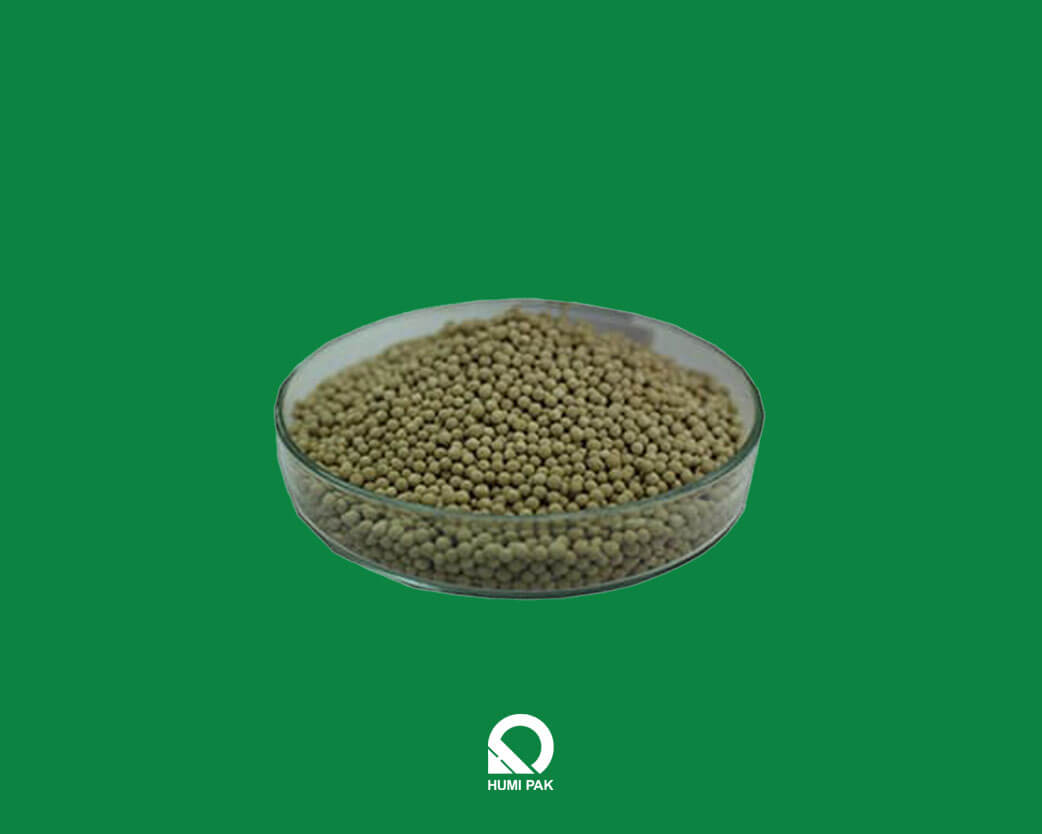

Molecular sieves are a unique class of adsorbents that selectively separate molecules based on size, shape, and polarity. Structurally, they comprise a network of uniform-sized pores and channels. These pores are created by the arrangement of silica and alumina tetrahedra, often forming a crystalline structure.

As the name suggests, these materials function as ‘sieves’ at a molecular level, allowing some molecules to pass through while blocking others. This selective filtration process is beneficial in applications where precise separation or purification is necessary. This article highlighted the intrinsic link between their efficacy and their packaging.

Basic Principles of Molecular Sieves

Molecular sieves are a category of porous materials that have the distinctive ability to separate particles on a molecular scale. They belong to the family of aluminosilicates and often manifest as crystalline metal-aluminosilicates such as zeolites.

Molecular sieves are a category of porous materials that have the distinctive ability to separate particles on a molecular scale. They belong to the family of aluminosilicates and often manifest as crystalline metal-aluminosilicates such as zeolites.

These materials are characterized by a three-dimensional network of interconnected channels and cavities with a consistent pore size. This uniformity enables them to selectively filter out molecules based on size, polarity, and shape.

Adsorption: At the heart of the molecular sieve’s function is the process of adsorption. When a mixture passes over the molecular sieve, certain molecules are attracted to and held onto the surface of the sieve’s pores.

The strength and specificity of this attraction are influenced by the nature of both the sieve material and the molecule being adsorbed. This means that some molecules will be preferentially captured while others will pass through, achieving a separation.

Desorption: The process is reversible. When conditions are altered (like changing the pressure or temperature), the captured molecules can be released from the molecular sieve’s surface. This process of releasing the adsorbed molecules is known as desorption. It allows for the regeneration and reuse of the molecular sieve, making them cost-effective for continuous industrial processes.

Key Characteristics and Properties:

- Uniform Pore Size: One defining feature is the consistent pore size, ensuring selective separation.

- High Adsorptive Capacity: They can capture a significant amount of material with a large surface area relative to their volume.

- Regenerability: They can be regenerated through desorption, allowing multiple uses without significant performance degradation.

- Thermal Stability: Most exhibit high thermal resistance, suitable for high-temperature processes.

- Chemical Inertness: They generally remain chemically inactive, ensuring the purity of separated materials and longevity.

- Selective Adsorption: Apart from size exclusion, these sieves can be tailored to adsorb certain molecules based on composition and polarity preferentially.

Types of Molecular Sieves

This categorization underscores the diversity and adaptability of molecular sieves, enabling their vast range of applications across different industries. These are some of the most common types, and they are differentiated mainly by their pore sizes, expressed in Ångstroms (Å).

- 3A: With a pore size of about 3 Å, they are typically used for drying solvents and removing moisture from gases, especially in removing water from ethanol.

- 4A: Having a pore size of around 4 Å, these sieves are employed for drying natural gases, refrigerants, and air streams. They can also remove impurities like CO2 and H2S.

- 5A: With a 5 Å pore size, they separate normal paraffin from isoparaffin, aromatic compounds, and other gases like O2, N2, and CO2.

- 13X: Featuring a larger pore size of 10 Å, 13X sieves are often used for general gas purification and can adsorb larger molecules, making them versatile in various applications, including air separation.

Zeolite-Based Sieves

Zeolite molecular sieves comprise alumina and silica tetrahedra, forming a crystalline, three-dimensional structure. They are naturally occurring minerals but can also be synthetically produced. Zeolite-based sieves are widely used in industries due to their high thermal stability, selective adsorption, and large internal surface area. Common applications include oil refining, petrochemical production, and air purification.

Carbon Molecular Sieves (CMS)

CMS is derived from a carbonaceous source subjected to a carbonization process. They possess a porous structure but differ from zeolite sieves regarding their chemical composition and adsorption mechanism. CMS primarily separates molecules based on size and shape, making them ideal for applications like nitrogen generation from air and hydrogen purification.

Applications of Molecular Sieves

These applications highlight the versatility of molecular sieve desiccants in addressing challenges across diverse industries, ensuring efficient operations and improved product quality.

Gas Separation: Molecular sieves excel in separating gas mixtures due to their precise pore sizes and selective adsorption capabilities. Common applications include:

- Air Separation: They can effectively separate nitrogen and oxygen from atmospheric air.

- Natural Gas Purification: Impurities like water, hydrogen sulfide, and carbon dioxide can be removed from natural gas streams.

- Hydrogen Purification: They can purify hydrogen from mixtures, making it suitable for industrial applications and fuel cells.

Drying of Liquids and Gases: Removing moisture is crucial in many industrial processes, and molecular sieves are often the preferred choice due to their high adsorptive capacities.

- Solvent Drying: Molecular sieves can achieve very low moisture levels in solvents, enhancing the efficiency of chemical reactions.

- Gas Drying: Industries such as natural gas and petrochemicals utilize them to remove water vapour from gases, preventing equipment corrosion and pipeline blockages due to ice formation.

Catalysis in the Petrochemical Industry: Molecular sieves act as catalysts, speeding up chemical reactions without undergoing permanent change.

- Cracking: They help break down larger hydrocarbon molecules into smaller, more valuable products.

- Isomerization: Molecular sieves can aid in rearranging the structure of molecules, transforming linear hydrocarbons into branched forms with different properties and applications.

Refrigeration and Air Conditioning: The ability of molecular sieves to adsorb moisture and other contaminants makes them invaluable in the refrigeration industry.

- Moisture Removal: By keeping refrigerant circuits dry, they prevent issues like corrosion, ice formation, and the breakdown of refrigerants.

- Acid Adsorption: They can capture acids that form in refrigeration systems, which could otherwise corrode equipment and reduce efficiency.

Medical Oxygen Concentration: Pure oxygen is vital for medical treatments, and molecular sieves have become instrumental in its production.

- Portable Oxygen Concentrators: These devices use molecular sieves to filter out nitrogen from the air, supplying patients with nearly pure oxygen.

- Large-Scale Oxygen Production: In hospitals and medical centres, molecular sieves generate large volumes of high-purity oxygen for various therapeutic applications.

Storage and Handling Recommendations

For specifics on any particular type or brand of molecular sieve, always refer to the manufacturer’s Material Safety Data Sheet (MSDS) or Safety Data Sheet (SDS) to receive tailored guidance on handling and storage practices.

Optimal Storage Conditions

Molecular sieves are highly hygroscopic and can rapidly absorb moisture from the surrounding environment. To maintain their efficiency and prolong their usability, storing them in airtight containers or well-sealed bags is essential, preventing any potential moisture intrusion.

While they are known for their thermal stability, storing them at ambient temperatures is recommended to ensure they remain at their optimal state for an extended period. Additionally, it’s crucial to keep them away from contaminants or volatile organic compounds to preserve their purity. Handling the containers carefully is also advised as, despite their robust nature, molecular sieves can become powdered or break upon strong impacts.

Shelf Life and Degradation

When stored under proper conditions, molecular sieves generally offer a long shelf life, remaining effective for several years. However, their lifespan and efficiency can diminish if they are repeatedly exposed to moisture or other contaminants. Indicators of degradation include diminished adsorption capabilities and visible changes in their appearance, such as clumping.

For those involved in critical industrial or scientific applications, periodic testing or monitoring of the molecular sieves is advisable to ensure they function at peak efficiency. One significant advantage of certain molecular sieves is their ability to be regenerated. Applying heat can effectively remove adsorbed substances and rejuvenate the sieves. However, always refer to the manufacturer’s guidelines to understand and implement the correct regeneration procedures.

Safety Precautions and PPE Recommendations

Handling molecular sieves, especially in their powdered form, poses a risk of dust inhalation. For this reason, wearing a mask or a respirator is a necessary safety measure. Although they aren’t typically harmful upon contact, prolonged exposure to the skin can lead to dryness or minor irritation; thus, protective gloves are advisable when handling or working with them.

Safety goggles are another essential piece of protective equipment, shielding eyes from potential irritation caused by dust or small particles. Ingesting molecular sieves is not recommended. Though they are generally non-toxic, any ingestion should be immediately addressed with medical consultation.

When working with these sieves, using specific tools like scoops or spatulas to minimize dust dispersal and guarantee precise handling is beneficial. In any spillage, careful sweeping or vacuuming ensures the material is collected without causing respiratory hazards.

Importance of Proper Packaging

Molecular sieves’ efficiency and shelf life hinge significantly on how they are packaged. Proper packaging ensures these sieves retain their adsorptive properties, safeguarding them from detrimental environmental factors like moisture, which can saturate their adsorption sites and compromise their effectiveness.

Additionally, as molecular sieves are often used in applications where purity is paramount, preventing contamination is crucial. Effective packaging extends the life of the molecular sieves and reduces economic losses due to reduced efficiency or the need for regeneration.

Conclusion

Molecular sieves are pivotal in various industries due to their unique adsorptive properties. Effective packaging guards against potential challenges like moisture and contamination, ensuring these sieves function at their best. As different sectors seek enhanced purity and efficiency, the emphasis on correct packaging becomes paramount.

Ultimately, the packaging not only stores but also preserves the integrity and performance of molecular sieves in numerous applications. Humi Pak, a certified ISO 9001 and 14001 manufacturer in Malaysia, produces premium molecular sieve desiccant bags. Our dedicated QA laboratory ensures quality. Free free to contact us for more details.