Humi Pak, based in Malaysia, is a certified manufacturer of desiccant packets, holding both 9001 and 14001 certifications. With daily quality assessments in our QA lab, we ensure quality products for our clients. Feel free to contact us for insights on desiccants and their reuse strategies.

Various Types of Desiccants and Their Performances

Desiccants are substances that absorb moisture from their surrounding environment. Used widely in various industries, their primary function is maintaining dryness in packaging and ensuring the contents remain unaffected by external humidity.

Controlling moisture in packaging is vital for several reasons. In many products, especially electronics and pharmaceuticals, moisture can negatively impact functionality and shelf life. Uncontrolled humidity can lead to spoilage, mould growth, or reduced quality of food items. Thus, effective moisture control, often achieved through desiccants, ensures product safety, longevity, and optimal performance.

What is a Desiccant?

A desiccant is a hygroscopic substance used to induce or sustain a state of dryness (desiccation) in its vicinity. In simpler terms, it’s a material designed to absorb and hold moisture. The primary purpose of desiccants is to reduce humidity in packaging or confined spaces, ensuring that products within those spaces remain dry and unaffected by ambient moisture.

Absorbing excess moisture prevents various potential issues, including mould growth, spoilage, oxidation, and degradation. For instance, in pharmaceutical packaging, a desiccant ensures that medicines retain their efficacy by preventing moisture-induced decomposition. Similarly, in electronic packaging, they prevent corrosion of components. By maintaining an optimal dry environment, desiccants effectively extend the shelf life of products, preserve their quality, and enhance their safety for end consumers.

Common Types of Desiccants

Desiccants serve the critical role of moisture control. Their variety is vast, with each type offering unique properties and applications. This section overviews the most prevalent desiccants, highlighting their characteristics and uses in different packaging scenarios.

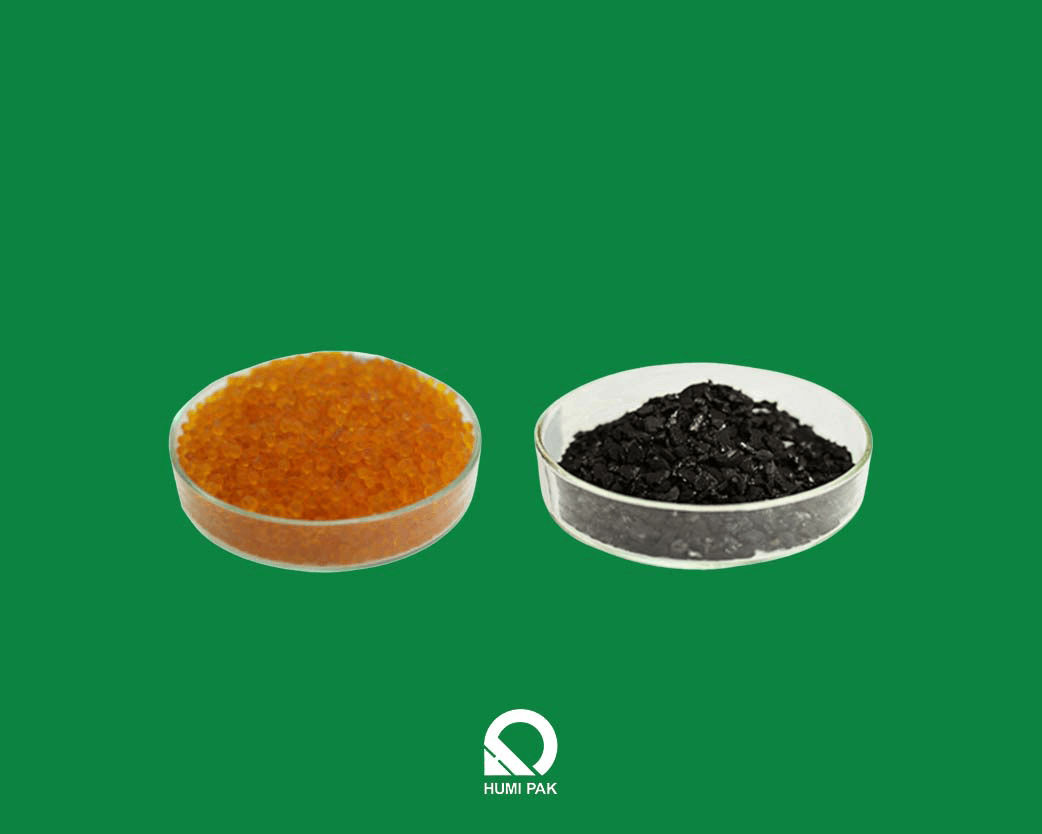

Silica Gel: A form of silicon dioxide (SiO2) synthetically produced into hard, irregular granules or beads. It’s non-toxic, non-flammable, and chemically inert. Its porous structure provides a vast surface area, enabling it to absorb up to 40% of its weight in water.

Silica gel is widely used in pharmaceutical packaging, electronics, food products, and leather goods. While it’s a versatile desiccant, its absorption capacity diminishes significantly at higher humidity levels. Moreover, it is less effective at very low relative humidity.

Calcium Chloride: A deliquescent salt that absorbs moisture from the air to form a brine solution. It can absorb water up to several times its weight.

It’s primarily used in shipping containers, bulk food packaging, and moisture control in basements or confined spaces. Its high absorption capacity makes it especially useful when water must be removed. However, since it becomes a liquid upon maximum absorption, it’s essential to consider containment in specific applications.

Activated Alumina: This desiccant is produced from aluminium hydroxide. It has a very high surface-area-to-weight ratio, with many tunnel-like pores. The material is hard and resistant to abrasion, and it does not shrink, swell, soften, or disintegrate when immersed in water.

Often used in gas drying, air separation, and as a purification agent for liquids, activated alumina is an excellent choice for applications that require high temperatures and acidic or alkaline environments. A drawback, however, is that it might lose effectiveness over time and may require periodic reactivation under high temperatures.

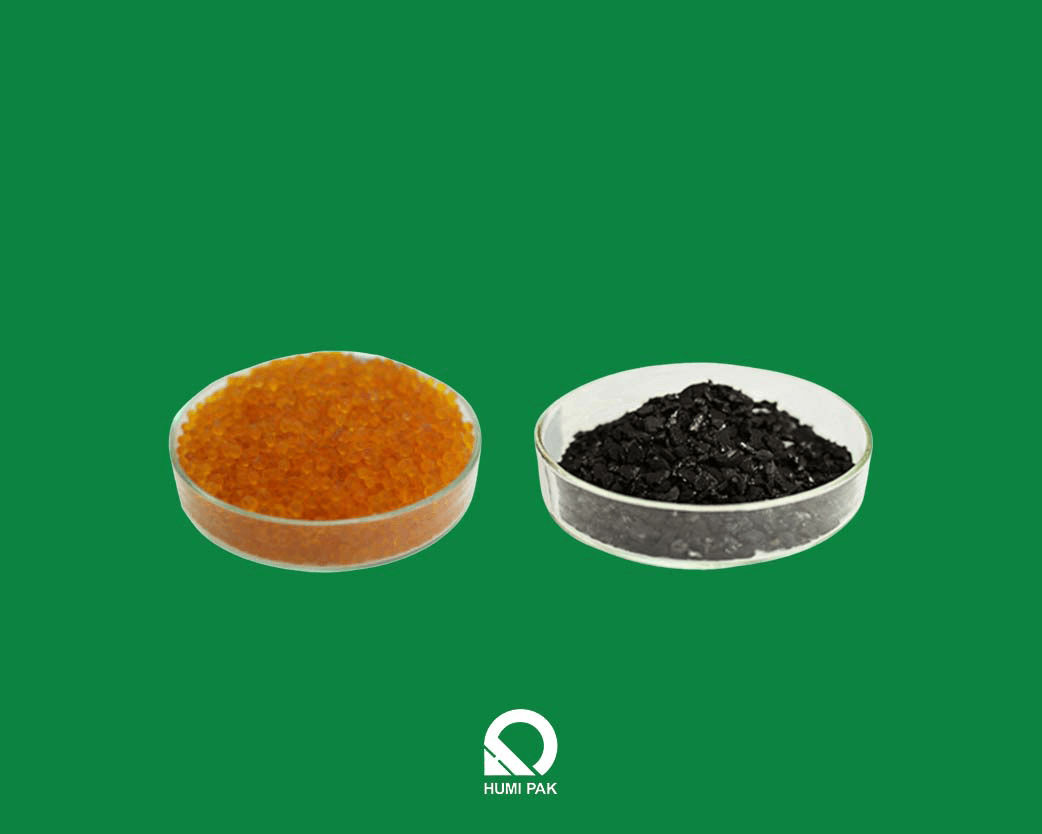

Clay (Bentonite/Montmorillonite): Clay desiccants are made from natural minerals such as bentonite or montmorillonite clay. They can absorb approximately 25% of their weight in water.

Often used in industrial packaging due to their low cost, clay desiccants are best used in moderate-temperature environments. They’re unsuitable for high-temperature applications because their moisture absorption capacity reduces significantly above 120°F.

Molecular Sieves: These are synthetic crystalline aluminosilicates with a regular and uniform pore structure. They work by trapping water molecules in their pores, excluding larger molecules and allowing smaller ones to enter.

These desiccants are extremely effective at low humidity levels and can reduce relative humidity in containers to below 10%. Molecular sieves offer rapid absorption rates and are commonly used in the pharmaceutical industry, petrochemical applications, and air drying systems. However, they are generally more expensive than other desiccants and can be reactive with certain chemicals.

Choosing the Right Desiccant

Selecting an appropriate desiccant is pivotal to product preservation, safety, and increased shelf life. By methodically assessing the product’s sensitivity to moisture, calculating the precise quantity of desiccant required, and carefully matching the desiccant to the packaging and storage environment, one can ensure the optimal preservation and performance of the product.

Assessing Product’s Moisture Sensitivity

Every product has a distinct relationship with moisture. Some items, such as electronics or certain pharmaceuticals, may be highly sensitive, with even minimal exposure leading to degradation, corrosion, or malfunction. The first step, therefore, is to accurately identify the moisture sensitivity level of the product in question.

Historical data and industry standards can provide invaluable insights, offering a peek into challenges faced by similar products or highlighting industry-accepted moisture thresholds. By understanding the maximum allowable moisture or relative humidity levels that a product can safely tolerate, one can form a foundational basis for their desiccant choice.

Calculating the Desiccant Quantity Required

Merely choosing the right desiccant type is not enough; determining the correct quantity is equally crucial. Several factors influence this decision. The volume of the space where the desiccant will function plays an obvious role. However, the relationship between space and required desiccant isn’t always linear, as factors like desired humidity level come into play.

If there’s a significant gap between the natural humidity and the desired level, the desiccant might need to work harder, necessitating a greater quantity. Furthermore, the intended protection duration will influence the amount needed for short-term shipping or long-term storage.

Different desiccants come with varying absorption capacities. For instance, while silica gel might absorb up to 40% of its weight in water, molecular sieves could handle more. Fortunately, many desiccant manufacturers provide desiccant calculation tools or reference tables to aid this decision, considering various influencing factors.

Matching Desiccant to Packaging and Storage Conditions

The surrounding environment and packaging can either bolster or hinder a desiccant’s performance. For instance, the permeability of packaging materials to moisture can dictate which desiccant is best suited for the task. If a packaging material already offers a high moisture barrier, the intensity with which a desiccant needs to function can be different than with more permeable materials.

Temperature is another crucial determinant. Since desiccants have varying performances across different temperature ranges, choosing one that remains effective under expected storage or shipping temperatures is essential. Additionally, for products with an extended shelf life, it’s imperative to ensure the chosen desiccant remains effective throughout its lifespan and doesn’t become saturated prematurely.

Regulatory standards, especially pertinent for food and pharmaceuticals, can also guide or limit desiccant choices. Lastly, while efficacy and safety are paramount, cost considerations often come into play. It’s a balance: the risks of potential product damage must be weighed against the expense of the desiccant.

Factors Influencing Desiccant Performance

The efficacy of a desiccant isn’t just reliant on its inherent moisture-absorbing properties but also a constellation of external factors. Understanding these factors ensures that the chosen desiccant performs optimally, safeguarding the product from moisture-related damage.

Environmental Conditions (Temperature, Humidity): The surrounding temperature can either enhance or diminish the moisture-absorbing capacity of a desiccant. For instance, certain desiccants might lose their efficacy at extremely high temperatures. Conversely, low temperatures might slow down the rate of moisture absorption. Humidity, as expected, directly impacts a desiccant’s workload. In high-humidity environments, desiccants work harder and can get saturated faster.

Packaging Materials and Barrier Properties: Some materials, like certain plastics or foils, have excellent moisture barrier properties, thereby reducing the amount of external moisture the desiccant has to contend with. Conversely, permeable materials might allow more moisture, demanding a more aggressive desiccant strategy. The interaction between the desiccant and the packaging material itself is also crucial. Some desiccants might have reactive properties with specific materials, leading to compromised integrity or product safety.

Volume and Air Space in Packaging: A larger air space or volume typically necessitates more desiccant to control moisture effectively. However, it’s not always about sheer volume; the shape of the space, the distribution of products within, and the air circulation patterns can also impact how efficiently a desiccant can pull in moisture. Inefficiently packed items, leading to irregular air pockets, might challenge maintaining consistent humidity levels.

Product Sensitivity to Moisture: Products highly sensitive to moisture might necessitate desiccants with rapid absorption rates or those that can maintain extremely low humidity levels. For such products, even minor fluctuations in moisture levels can be detrimental. Conversely, for products with moderate or low sensitivity, there might be more leeway in desiccant choice and performance metrics.

Conclusion

The use of desiccants in packaging hinges on several critical factors. The right choice of desiccant isn’t a one-size-fits-all solution. It requires a careful consideration of multiple elements. Ensuring the correct selection and application can greatly enhance product shelf life and quality.