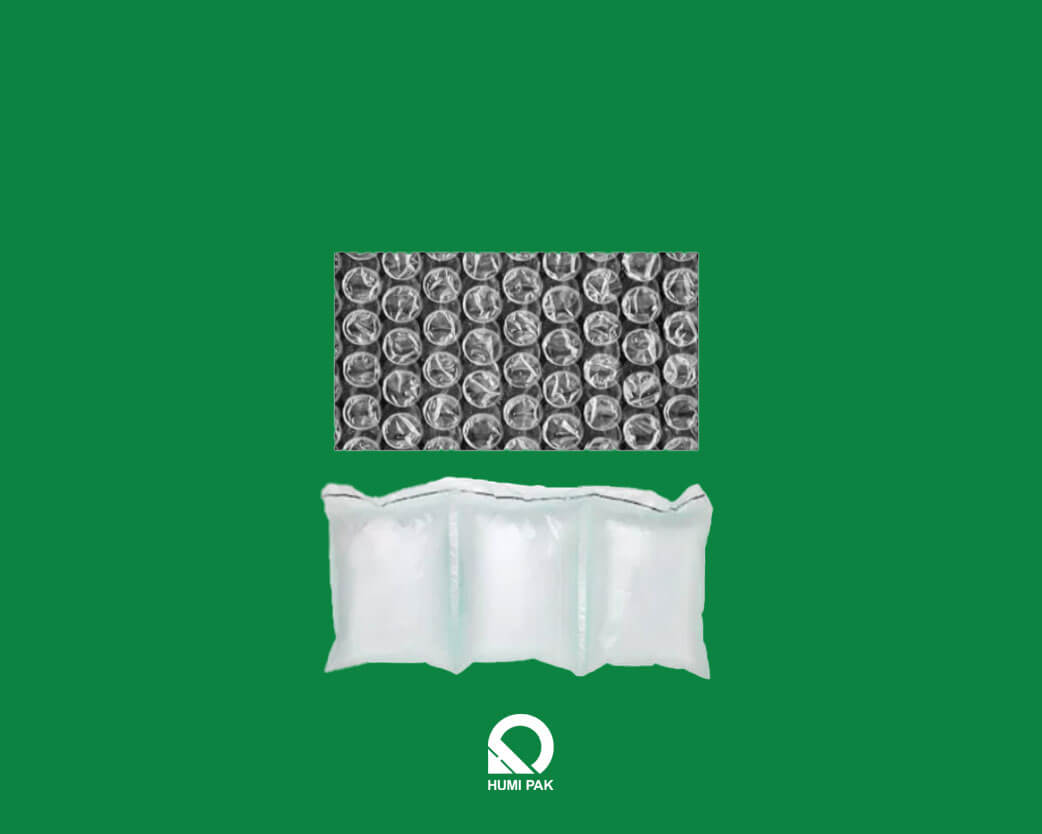

Bubble Wrap vs Air Pillow Packaging

Packaging is integral to every use, ensuring products are protected, preserved, and presented effectively. As global trade has expanded, so needs reliable packaging solutions that can withstand the rigours of transportation—ensuring that fragile electronics or perishable goods arrive at their destinations undamaged. This article aims to compare bubble wrap and air pillow packaging, highlighting their benefits and exploring which might be the optimal choice for various needs.

Understanding Bubble Wrap

Bubble wrap is a transparent plastic material for packaging and cushioning fragile items. It consists of a sheet of thin plastic film with regularly spaced, protruding air-filled bubbles. These bubbles provide cushioning and absorb shocks during transportation, protecting the items enclosed within.

Primarily constructed from low-density polyethene (LDPE) resin, this popular cushioning material consists of a continuous film with uniformly distributed air-filled pockets. The manufacturing process involves extruding LDPE into two sheets and trapping air between them to form protective bubbles.

Efficiency in Product Protection

Cushioning Properties: The primary strength of this packaging material lies in its design: air-filled pockets embedded in a flexible plastic sheet. These pockets act as mini air cushions, distributing pressure and preventing direct impacts on the protected item. This distribution minimizes localized stress, reducing the likelihood of breakage or damage. Whether it’s a fragile porcelain figurine or a sensitive electronic device, the material’s cushioning ensures that items are cocooned safely, even when subjected to external pressures during transport.

Shock Absorption Capabilities: Beyond mere cushioning, its true prowess emerges when faced with sudden impacts or jolts. The air within the pockets acts as a buffer, compressing and expanding to absorb and dissipate shock energy. This dynamic response reduces the force transmitted to the enclosed item. As a result, even if a package is dropped or mishandled, the chances of the contents remaining unharmed are significantly increased. The larger the pockets, the more air they contain, often leading to better shock absorption, especially for heavier items.

- Effective Cushioning: Its air-filled pockets absorb shocks and impacts, greatly reducing the risk of damage during transit.

- Versatility: Its flexibility allows it to conform to a wide range of shapes, from flat surfaces to irregular objects.

- Lightweight: Adds minimal weight to packages, helping to keep shipping costs down.

- Cost-effective: Often more affordable than other protective packaging options, making it a popular choice for businesses and individuals alike.

- Reusable: It can be used multiple times with care, extending its utility and reducing waste.

- Tactile Satisfaction: Though not a primary function, many individuals find popping its pockets a pleasurable and stress-relieving activity.

Functionality and Usage:

This cushioned material is extensively used across various industries, serving as a protective layer for fragile items during transport and storage. Common uses include:

- Wrapping electronics, ceramics, glassware, and other breakables.

- Filling voids in boxes to prevent item movement.

- Lining the inside of shipping envelopes for smaller delicate items.

- Insulating windows in colder climates (due to their air-filled pockets).

- Providing a protective surface for storing artwork or antiques.

Understanding Air Pillows

Air pillows are designed to provide protection and cushioning for shipped goods. Instead of the traditional bubble shape found in bubble wrap, air pillows are elongated, filled with air, and often connected in a chain-like manner. They are typically used to fill voids in boxes, ensuring products remain stationary and protected during transit.

Like bubble wrap, air pillows are usually made from lightweight and durable plastic polyethene. They are produced by sealing two sheets of plastic together in a pattern that forms multiple pillows, which are then inflated with air before or during packaging.

Using an air pillow machine allows businesses to inflate pillows on-site, giving flexibility in determining the air volume and the number of pillows needed. Air pillows are primarily used to fill void spaces within packages to prevent items from shifting, rather than wrapping the items directly. The air inside provides cushioning against shocks during transportation.

Efficiency in Product Protection

Air pillow packaging can retain air over time, ensuring persistent cushioning. The enclosed air acts as a barrier, absorbing shocks and impacts that might otherwise directly affect the product.

Consistent Barrier: Unlike some packaging materials that might get compressed or lose their protective properties, air pillows maintain a consistent protective barrier. The sealed polyethene ensures minimal air loss during transit, thus retaining its cushioning properties.

Impact Dispersion: When external force is applied, the air inside the pillow disperses the force, reducing the direct impact on the product. The interconnected design of many air pillow chains further aids in distributing the pressure across multiple pillows, enhancing protection.

Customizable Size and Air Volume: Depending on the machinery or system in use, businesses can adjust the size of the air pillows and the volume of air they contain. This means packaging for a delicate ceramic figurine might use smaller, tighter air pillows, while a larger electronic device might benefit from larger, more robust pillows.

- Space Efficiency: Unlike pre-inflated packaging materials, air pillows can be inflated on demand, reducing storage space requirements.

- Weight: Being filled with air, they are extremely lightweight, which can result in lower shipping costs.

- Versatility: They can be used in various package sizes and configurations, adjusting the number of pillows as needed.

- Recyclability: Made from polyethene, they can be recycled where facilities exist for this type of plastic.

- Adaptability: One of the standout features is their adaptability. Businesses can inflate the exact number they need, controlling volume and size based on the package’s requirements.

- Consistent Cushioning: Uniform size and shape ensure consistent cushioning throughout the package, reducing the risk of damage.

Functionality and Usage:

Air pillow packaging, with its distinctive elongated pockets of air, is versatile in application.

- Void Filling: One of the primary uses of air pillows is to fill the empty spaces in boxes, ensuring that products remain stationary during transit. This prevents movement and potential damage to the items inside.

- Stacking Support: When boxes contain multiple items, air pillows can be used as layers in between, providing cushioning and preventing products from pressing against each other.

- Edge and Corner Protection: The pillows can be placed around the edges or corners of products to offer protection against impacts.

- E-Commerce Shipments: With the surge in online shopping, air pillows have become a favourite for e-commerce businesses, offering protection for various products, from electronics to cosmetics.

- Fragile Items: Though not wrapped directly around the item like bubble wrap, air pillows surrounding a fragile item in a box can offer adequate protection against shocks.

Bubble Wrap vs. Air Pillow Packaging

| Feature/Aspect | Bubble Wrap | Air Pillow Packaging |

|---|---|---|

| Material | Low-density polyethylene (LDPE) | Usually polyethylene |

| Primary Use | Wrapping around products | Void filling in boxes |

| Cushioning Mechanism | Air-filled bubbles | Elongated air-filled pockets |

| Weight | Lightweight but varies with size | Extremely lightweight |

| Storage Space Needed | Relatively more (pre-inflated) | Minimal (inflatable on-demand) |

| Protection Efficiency | Effective for direct wrapping | Effective for void filling |

| Adaptability | Flexible for various products | Customizable size and air volume |

| Environmental Impact | Slow to biodegrade | Recyclable where facilities exist |

| Production Cost Factors | LDPE prices, energy costs, scale | Material cost, inflation, technology |

| Market Presence | Ubiquitous in packaging | Growing, especially in e-commerce |

Both bubble wrap and air pillow packaging are solutions for safeguarding products during transportation. Each boasts its unique attributes tailored to distinct scenarios and needs. Bubble Wrap, known for its air-filled pockets, provides direct wrapping protection and is suitable for diverse products. Its design emphasizes shock absorption, making it a reliable choice for fragile items.

On the flip side, Air Pillow Packaging, characterized by its elongated air-filled pouches, is predominantly used for void filling. Its on-demand inflation reduces storage issues, and its lightweight structure can save shipping costs. Its primary advantage lies in filling empty packaging spaces, ensuring transit stability.

While both offer protective solutions, their applications and strengths differ. The choice between them depends on specific packaging requirements, each with unique advantages. Humi Pak offers a comprehensive range of packaging solutions, including bubble wrap and air pillow packaging. Contact us for a consultation, and our packaging engineers will be delighted to provide a hands-on demonstration of both products.