What are Oxygen Absorbers?

Oxygen absorbers or Oxygen scavengers, commonly found in many packaged products, are designed to safeguard the contents from the detrimental effects of oxygen exposure. While oxygen is essential, its presence in closed packages can lead to product degradation, particularly in food items, by accelerating spoilage, altering colour, and reducing nutritional value.

Similarly, oxygen can hasten oxidation processes in non-food items like electronics or metals, leading to rust or other damage. As the demand for longer shelf life and product integrity grows, the importance of these absorbers in preserving the quality of packaged goods becomes ever more evident. This article delves into the science, application, and benefits of oxygen absorbers in packaging.

Understanding Oxygen Absorbers

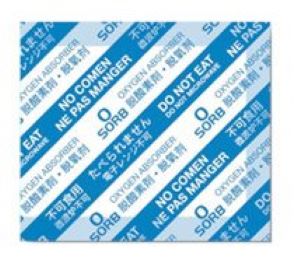

Oxygen absorbers are small sachets or packets designed to remove and maintain low oxygen levels within a sealed environment. Their primary role is to protect the contents of a package from the harmful effects of oxygen, thereby extending the product’s shelf life and maintaining its quality.

They are made of a chemical compound that reacts with oxygen to remove it from the surrounding environment. The most common type of oxygen absorber uses iron powder as its primary active ingredient. When exposed to oxygen, the iron oxidizes, turning into iron oxide. This process effectively “absorbs” the oxygen from the air inside the package. Alongside iron, these packets often contain salt and activated charcoal, which aid in absorption and prevent the release of unwanted gases.

When the iron inside the absorber comes into contact with oxygen, it forms iron oxide through oxidation. The equation can represent this reaction:

When the iron inside the absorber comes into contact with oxygen, it forms iron oxide through oxidation. The equation can represent this reaction:

3 Fe (iron) + 4 O₂ (oxygen) → 2 Fe₃O₄ (iron oxide).

The creation of iron oxide means that the oxygen previously present in the package’s air is now bound in a solid form, effectively reducing the concentration of free oxygen inside the package. This process ensures that the environment within the packaging remains largely oxygen-free, protecting the product from spoilage, oxidation, and other oxygen-related degradations.

Benefits and Advantages

Oxygen absorbers in packaging do more than prolong product life. It ensures that consumers receive items in their best possible state, enhancing their overall experience and trust in brands.

Extending Shelf Life: Reducing the oxygen levels inside sealed packages slows oxidation reactions and microbial growth, ensuring products last longer on shelves. This longer shelf life benefits manufacturers, retailers, and consumers economically. It means reduced wastage, longer selling periods, and more flexibility in buying and consuming products.

Preserving Color, Texture, and Taste: By limiting oxygen exposure, these absorbers help maintain the original appearance, consistency, and flavour of products. Consumers experience products as they are intended, leading to increased satisfaction and brand trust.

Preventing Mold, Mildew, and Spoilage: Removing oxygen significantly inhibits their growth, ensuring products remain unspoiled. This ensures the safety and edibility of food products and reduces the risk of health issues related to mould and mildew consumption.

Reducing the Need for Preservatives and Additives: As consumer demand shifts towards more natural and minimally processed products, the ability to reduce or eliminate preservatives becomes a significant selling point. This leads to cleaner labels, a boon for health-conscious consumers.

Applications and Industry Usage

Food Packaging: Dry foods, such as grains, nuts, dried fruits, and powdered goods, are naturally vulnerable to oxidation and pests. Including protective sachets in their packaging is an effective countermeasure, shielding them from spoilage and potential infestations. On the other hand, fresh foods, like meats and cheeses, demand different care. Oxygen can be particularly detrimental, causing discolouration and promoting bacterial growth.

Using these sachets helps combat these issues, ensuring products maintain their fresh appearance and taste for longer durations. Finally, ready-to-eat meals, including retort pouches and MREs (Meals Ready-to-Eat), have become staples in our fast-paced society. For such products, they must remain palatable over extended storage periods.

Pharmaceutical Packaging: Medications, irrespective of their form, can degrade or lose potency upon exposure to oxygen. Any alteration to a medication’s intended composition can compromise its efficacy and, in worst cases, lead to harmful by-products. It’s imperative, then, to maintain the integrity and safety of medicines throughout their shelf life.

Electronic Components Packaging: Such components are susceptible to oxidation, severely impairing their functionality and lifespan. To ensure that these components continue to operate at peak performance, protective sachets are sealed alongside them during packaging.

Artefact and Document Preservation: Many historical items, especially those made of organic materials like leather or fabric, can deteriorate when exposed to oxygen. Similarly, documents, particularly old manuscripts or photographs, can fade or become brittle. Museums, archives, and collectors recognize these challenges and thus utilize protective sachets when storing these invaluable items.

Choosing the Right Oxygen Absorber

Oxygen absorbers come in various sizes and capacities, measured in terms of the volume of oxygen they can remove (usually denoted in cubic centimetres or cc). Larger packaging or items with a higher internal air volume will naturally require absorbers with a greater capacity. The capacity is measured in CC (cm3), a unit of measurement equal to millilitres (ml). For example, 20 cc = 20 ml. So, 20 cc Oxygen Absorbers will absorb 20 cm3 of oxygen.

| Bag Size | Refined Grains (sugar, flour, etc.) | Pasta and Thicker, Less Dense Foods |

| 6″ x 6″ | 20 CC | 50 CC |

| 8″ x 8″ | 50 CC | 100 CC |

| 10″ x 14″ | 100 CC | 200 CC |

| 10″ x 16″ | 150 CC | 300 CC |

| 16″ x 18″ | 500 CC | 1000 CC |

| 18″ x 28″ | 750 CC | 1500 CC |

| 20″ x 24″ | 750 CC | 1500 CC |

| 20″ x 30″ | 1000 CC | 2000 CC |

Safety, Handling and Best Practices

Oxygen absorbers are generally not toxic. They are designed to remove oxygen from packaged environments safely. The primary ingredient in most of these packets is iron powder, which oxidizes to form iron oxide when it reacts with oxygen. Iron oxide is a harmless compound. However, it’s worth noting that while the contents aren’t typically toxic, they are not meant for ingestion.

They are not likely to cause harm if ingested, but seeking medical advice is recommended. Once they have served their purpose, oxygen absorbers can be disposed of in regular trash. Since their primary component is often oxidized iron (rust), they are environmentally benign. Some people even open up the used packets and add the iron oxide to their gardens as a soil supplement, although this isn’t a widely practised method.

Precautions for Manufacturers and End-Users:

- Do Not Eat: Though typically non-toxic, keeping them out of the reach of children and pets is crucial. They are not food; their packaging often clearly states “Do Not Eat.”

- Prompt Usage: Once the bulk packaging of these absorbers is opened, they should be used promptly or resealed tightly to retain their effectiveness.

- Avoid Direct Contact: For those handling large quantities, wearing gloves is a good idea to prevent skin irritation and to avoid any reaction between the absorber and skin moisture.

- Check for Intactness: Ensure that the packets are not damaged or torn before using, which could lead to their contents spilling into the packaged product.

- Educate End-Users: Manufacturers should provide clear instructions to end-users about the purpose of the absorbers, emphasizing that they should not be consumed.

Storage Before Use:

- Avoid Exposure: Oxygen absorbers begin their work as soon as they’re exposed to air. Hence, before they’re used, they should be kept in their original sealed packaging to prevent premature activation.

- Cool and Dry: Store the absorbers in a cool, dry place. Humidity and heat can affect their efficiency and shelf life.

- Bulk Handling: If you purchase absorbers in bulk, consider repackaging them into smaller quantities. This way, when you open a pack, you’ll only expose the quantity you need, leaving the rest sealed and fresh for later use.

- Quick Use: Once the absorbers’ packaging is opened, they must be used as quickly as possible. Prolonged exposure to ambient air will reduce their effectiveness.

Proper Placement Within the Package:

- Surface Contact: Ensure the absorber is nearby or in direct contact with the product. This maximizes its efficiency in removing oxygen from around the product.

- Avoid Obstruction: Ensure no barriers, like dividers or other inserts, might prevent the free circulation of air around the absorber.

- Mind the Space: While using an absorber with the right capacity is essential, avoid using one that’s too large for the package, as it can take up unnecessary space or affect product placement.

Sealing the Package Effectively:

- Airtight Seal: The efficacy is significantly diminished if the package isn’t sealed airtight. Ensure that there are no leaks or punctures in the packaging material.

- Quality of Sealants: Use high-quality sealants and ensure sealing equipment (like heat sealers) is in good working condition and set at the correct temperature.

- Check for Defects: Before and after sealing, it’s good practice to check packages for any defects that might allow air to enter. This can be done using visual inspections, pressure tests, or other suitable methods.

Conclusion

Minimizing food spoilage or product degradation directly reduces waste, a pressing concern for many sectors. Furthermore, oxygen absorbers can simplify ingredient lists and promote cleaner labelling by potentially reducing the need for other preservatives.

Humi Pak offers an extensive selection of oxygen absorbers manufactured utilizing advanced Japanese technology and materials. Please contact us if you’re interested in samples or require more details. Our packaging engineers are available for consultations and appointments to assist you further.