All About Volatile Corrosion Inhibitors (VCI)

Volatile Corrosion Inhibitors, or VCIs, are compounds used to protect metal surfaces from corrosion. Releasing vapours that form a protective layer on metals effectively deter rust and degradation. They address the fundamental need to preserve products during storage and transit, ensuring goods retain their quality. The role of VCIs in packaging is used especially in industries where corrosion can impact product efficacy and safety.

Understanding Corrosion

Corrosion is the natural process where materials, primarily metals, deteriorate due to chemical interactions with their environment. At a basic level, it’s the result of the metal reacting with oxygen in the presence of moisture, leading to the formation of oxides. For metals like iron, this process results in rust.The concern with corrosion is multifaceted. Firstly, it compromises the material’s structural integrity, reducing strength and potential failures.

This can be especially concerning for items that rely on metallic strength or electrical conductivity. Corrosion occurs when there’s an electrolyte on a metal’s surface, facilitating the flow of electrons from high-energy regions of the metal to its low-energy areas. This electron flow forms a loop through the electrolyte, resulting in the oxidation of the metal surface, commonly recognized as rust or tarnish. Common materials in packaging that are susceptible to corrosion include:

- Iron and Steel: Often used in tools, machinery parts, and certain containers, these materials are particularly vulnerable to rust when exposed to moisture.

- Aluminium: Used in cans, foils, and certain lightweight packaging, aluminium can corrode, forming a white powdery substance called aluminium oxide.

- Copper and its Alloys (like bronze and brass): Common in electrical components and decorative items, these materials can tarnish or develop a green patina when corroded.

- Zinc: Often used as a coating for other metals to prevent their corrosion, zinc can corrode when the coating is damaged.

However, this corrosive process is disrupted with Volatile Corrosion Inhibitors (VCIs). VCIs prevent the flow of the electrical current between the anode (high-energy area) and the cathode (low-energy area) by creating an imperceptible protective film. These VCI molecules adhere to the metal’s surface, shielding it from corrosion and extending its lifespan.

How VCIs Work

VCIs are organic compounds that, when introduced into a packaging environment, vaporize into the surrounding atmosphere. These vapours are attracted to metal surfaces due to charge disparities, chemical affinities, or other molecular interactions. Once they come into contact with these surfaces, they condense, forming a thin, invisible protective layer. This layer is molecularly aligned, presenting a barrier to the corrosive agents, such as moisture, oxygen, and salts.

Adsorption: VCIs work primarily through adsorption, where molecules adhere to the surface of the metal, creating a barrier that prevents corrosive elements from reaching the metal.

Adsorption: VCIs work primarily through adsorption, where molecules adhere to the surface of the metal, creating a barrier that prevents corrosive elements from reaching the metal.

Passivation: Some VCIs can induce passivation, where they react with the metal surface to form a thin, protective oxide layer, further enhancing the metal’s resistance to corrosion.

pH Modification: Certain VCIs can modify the pH of the moisture on a metal surface, making the environment less conducive to corrosion.

Electrochemical Disruption: At the molecular level, VCIs interfere with the electrochemical process of corrosion. By disrupting the flow of electrons, they halt the anodic and cathodic reactions that drive the corrosion process.

Vapour Pressure Equilibrium: VCIs balance their solid or liquid state and their vapour state within the packaging environment. This ensures a continuous supply of protective molecules to shield the metal surface.

Types of VCIs

Volatile Corrosion Inhibitors (VCIs) come in various chemical compositions and categories, tailored to meet specific industrial needs and protect various metal types. They come in a diversified range tailored to different applications, from papers and liquids to films, bags, emitters, and more.

- VCI Paper: Designed for wrapping metal items or layering within a container, these papers are infused with VCI compounds on both sides, ensuring comprehensive protection from corrosion.

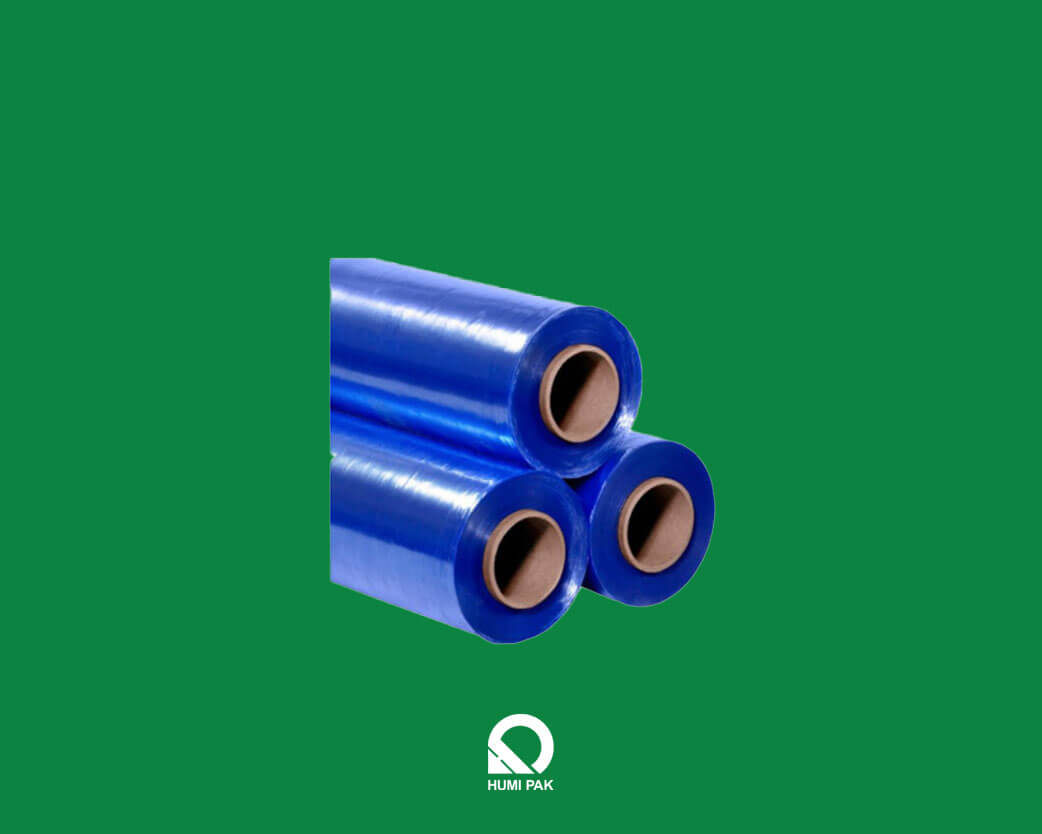

- VCI Film: Suited for larger equipment, these films come in rolls that, when unwound, offer a protective layer with vapour corrosion inhibitors, shielding metals from rust and tarnish.

- VCI Liquid: Upon application, the VCI compounds in the liquid adsorb onto the metal’s surface, forming a water-repellent barrier that safeguards against moisture-induced corrosion.

- VCI Emitter: These are compact discs laden with VCIs. Due to their slim profile, they easily fit into tight spaces, releasing corrosion inhibitors to protect otherwise inaccessible areas.

- VCI Bags: Ideal for assembly and packaging processes, these bags are uniformly coated with VCI compounds. They act as effective barriers, preventing corrosive agents from reaching the enclosed metals.

- VCI Powder: This formulation is primarily for void spaces and internal cavities. Whether dusted directly, fogged into enclosures, or used as a solution, the powder offers robust protection, especially in lay-up and preservation scenarios.

Applications and Industries

Volatile Corrosion Inhibitors are widely adopted across various industries due to their effective corrosion protection. VCI packaging has become a standard choice for maintaining product quality during storage and transit from electronics to aerospace.

- Application: Electronic components, especially those with metal parts, are susceptible to corrosion, which can impair functionality. VCI packaging offers protection during storage and transit.

- Real-world example: Major electronics manufacturers use VCI bags to store and ship circuit boards. In one case, a leading computer hardware company reported a significant reduction in returns and complaints related to corrosion after switching to VCI packaging for overseas shipments.

Automotive:

- Application: Automotive parts, from engines to brake components, benefit from VCI protection, especially during international shipments or long-term storage.

- Real-world example: A global car manufacturer faced challenges with rusted parts arriving at assembly plants. By shifting to VCI wraps and films, they ensured that parts remained corrosion-free even during multi-week sea voyages.

Aerospace:

- Application: Aerospace components have stringent quality and safety standards. VCI packaging is used to maintain the integrity of these parts, especially those stored for extended periods or transported over long distances.

- Real-world example: After overhauling engines, an international airline used VCI emitters in the storage area. This move dramatically reduced instances of corrosion-related wear during subsequent operations.

Metal Fabrication:

- Application: Raw metal sheets, rods, and finished components in the metal fabrication industry need protection against environmental factors leading to corrosion.

- Real-world example: A large metal fabrication unit producing parts for the construction industry started using VCI powders in their packaging. This change led to a notable decline in customer complaints related to rusted components.

Benefits of VCI Packaging

Metals transported or stored often face the risk of corrosion. When VCIs are used, molecules are released and adhere to the metal surfaces, forming a barrier against corrosive agents like moisture and oxygen. Some molecules attach directly from the film or paper, while others vaporize within the packaging, settling on metal surfaces not in direct contact with the VCI material.

Once the metal is unpacked, any remaining VCI molecules evaporate, ensuring the metal is ready for use without further treatment. There are several benefits to VCI technology. It negates the need to remove additional coatings or oily rust preventatives, saving time and reducing waste disposal challenges.

It’s particularly effective for complex equipment internals, such as pipes or boilers, where traditional methods are less practical. Unlike some dehumidification systems, VCIs don’t rely on electricity and are versatile enough to work on various metals in different states—liquid, vapour, or interface. This makes them useful in sectors like water treatment or oil and gas.

Extended Product Lifespan

The durability of products is a significant concern for manufacturers and consumers. VCI packaging directly addresses this concern by offering an extended lifespan to the products it encases.

Preventing premature corrosion means that metal components, machinery, tools, and other susceptible items maintain their usability and functionality over extended periods. This durability is not merely an operational advantage; it has a ripple effect on brand perception and customer relations.

Environmental Advantages

In today’s ecologically-conscious world, the environmental impact of any industrial solution is under the spotlight. VCI packaging steps up to this challenge commendably. One direct benefit is the significant waste reduction. Longer-lasting products mean fewer items are discarded or returned due to corrosion-induced damage.

This decrease in waste contributes to a smaller ecological footprint, benefiting both businesses in terms of disposal costs and the broader environment. Additionally, the emphasis on creating VCIs that are environmentally friendly ensures products are protected without resorting to hazardous chemicals.

Protection During Transportation and Storage

One of the primary roles of any packaging solution is maintaining the integrity of the products, especially during transportation and prolonged storage. By creating a protective molecular barrier, VCIs shield products from often harsh environments, especially from elements like moisture, air, and other corrosive agents.

This protective feature ensures goods remain undamaged and pristine from the point of packaging to the end-user. Moreover, by actively preventing corrosion, businesses can realize substantial cost savings. The reduced incidence of damaged goods translates to fewer replacements, fewer returns, and an overall enhancement in profitability.

Conclusion

Volatile corrosion inhibitors (VCIs) effectively prevent corrosion during transportation and storage; they maintain product quality and reduce losses. Their application simplifies the packaging process, reduces the need for other preventive measures, and offers a reliable solution to a pervasive problem.

Humi Pak Sdn Bhd specializes in a wide range of volatile corrosion inhibitors. Using them is straightforward: wrap metal components or products, ensuring the edges are neatly folded to minimize air exposure. For added security, adhesive tape can hold these folds in place. Beyond the standard offerings, we’re equipped to furnish custom solutions tailored to specific needs, available as bags, wraps, or sheets, and in various materials and dimensions. To ensure our clients are well-informed, we readily provide data sheets and extend dedicated technical support for all our products.