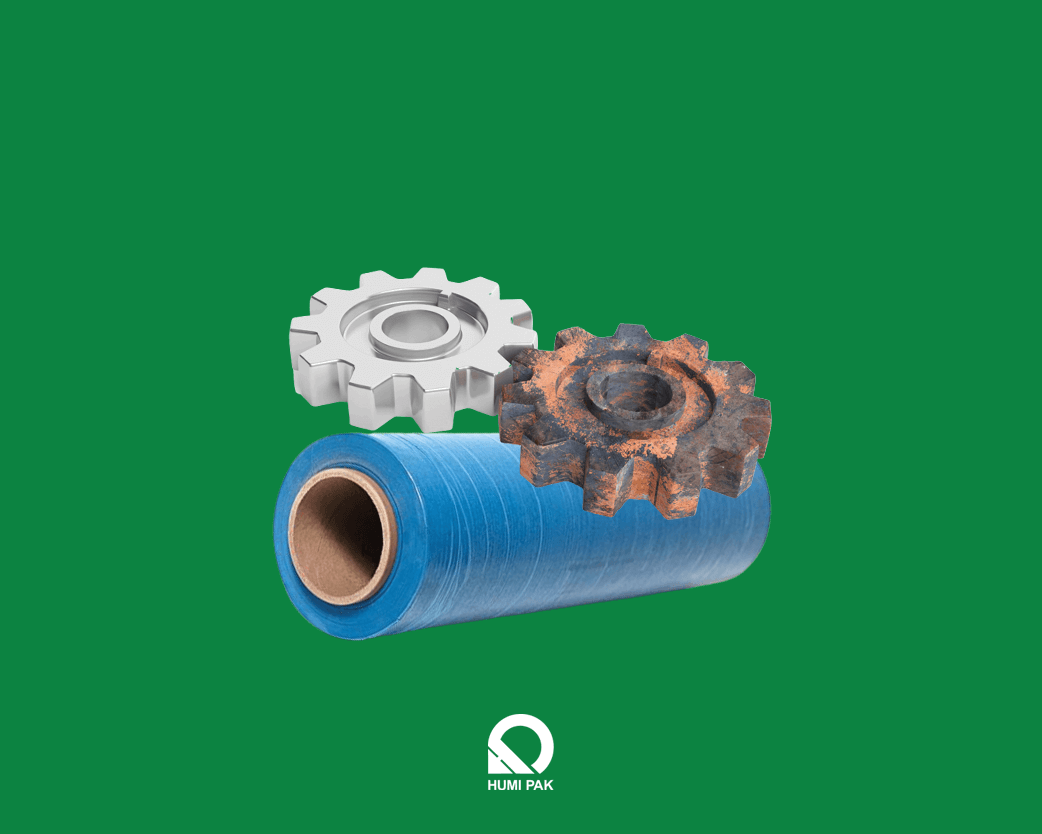

Avoid Corrosion Costs with VCI

Regarding businesses that rely on non-corroded metal to function, rust can have unexpected effects, such as decreased productivity, accidents, and significant financial loss. Every year, companies lose billions of dollars in operations due to corrosion alone. A study by NACE International (International Measures of Prevention, Application, and Economics of Corrosion Technology Study) illustrates precisely how severe and costly the corrosion problem is. It is estimated to cost $2.5 trillion (USD), which does not account for personal safety or environmental effects.

This $2.5 trillion figure is about 3.4% of the world’s gross domestic product (GDP). Implementing corrosion controls can help businesses save money. According to a survey by NACE International, the total annual savings worldwide might range from $357 to $875 billion (USD) if more people adopt solutions. VCIs are a packaging solution to guard metals against corrosion, utilizing vapour-phase protectants that shield even the most inaccessible parts. In the article, we’ll provide a comprehensive overview of VCIs, underscoring their importance in corrosion prevention strategies.

What is Corrosion?

Corrosion is the natural process by which a refined metal deteriorates into a more stable form, such as its oxide, hydroxide, or sulfide. This deterioration is an electrochemical reaction between the metal and its surrounding environment, leading to the eventual degradation of the material. For example, when exposed to moist air, iron transforms into iron oxide or what we commonly recognize as rust. Several factors can accelerate the corrosion process:

- Presence of Electrolytes: Saltwater, for instance, acts as an electrolyte that can speed up the corrosion of metals.

- Oxygen Concentration: Corrosion can be more aggressive in areas with higher oxygen concentrations.

- Acidity or Alkalinity (pH Levels): Metals corrode faster in extremely acidic or alkaline environments.

- Temperature: Higher temperatures can accelerate the rate of many corrosion reactions.

- Chemical Exposure: Exposure to certain chemicals can heighten the risk of corrosion for specific metals.

- Microbial Activities: Certain microbes can induce corrosion through various metabolic processes.

Impact of Corrosion on Materials

Corrosion’s consequences extend far beyond mere surface degradation. Corroded materials, for instance, lose their inherent strength over time. This weakening, often imperceptible at the outset, jeopardizes their structural integrity, rendering them susceptible to unexpected failures.

The financial toll of corrosion is equally pressing. The inevitable wear and tear demand frequent repairs and replacements, incurring additional costs. Moreover, the maintenance these materials require often means downtime, which, in a domino effect, leads to losses in productivity.

The performance of machinery and equipment can significantly impede their efficiency. A case in point is the corrosion inside pipes, which can cause obstructions, restricting the seamless flow of fluids. Another often overlooked concern is contamination. As materials corrode, they can contaminate the products they come into contact with. Such contamination can be particularly detrimental in sectors like food processing or pharmaceuticals, where purity and hygiene are paramount.

Understanding Volatile Corrosion Inhibitors

VCI are chemicals that vaporize and release into the surrounding environment, creating a protective molecular layer over the surface of metals. This molecular layer interrupts the electrochemical corrosion process by either forming a barrier between the metal and corrosive agents or passing the metal’s surface, reducing its reactivity. The volatile nature of VCI ensures that even the nooks, crannies, and hard-to-reach areas of items are shielded, providing comprehensive protection. Using VCI technology has several advantages:

- Comprehensive Protection: VCIs protect even the most challenging areas, ensuring an all-encompassing shield against corrosion.

- Cost-Efficiency: VCIs help reduce maintenance and replacement costs in the long run by preventing corrosion.

- Ease of Application: VCI solutions, whether in films, papers, or emitters, are straightforward to apply.

- Environmentally Friendly Options: Many VCIs are designed to be environmentally benign, aligning with sustainability goals.

- Safety and Cleanliness: VCIs often eliminate the need for oils or greases, leading to cleaner storage and shipping conditions.

Application of VCI in Packaging

Using VCI in packaging offers industries a solution against the problem of corrosion, ensuring that products retain their quality, functionality, and appearance throughout their journey from manufacturer to end-user.

VCI Films and Bags: These films are embedded with VCI compounds that volatilize when in proximity to metals, forming a protective molecular layer that prevents the onset of corrosion. They are especially useful for parts with intricate geometries or are difficult to coat uniformly with traditional anti-corrosion treatments. VCI bags offer an additional benefit of sealing the product, ensuring a controlled environment.

VCI Paper: Infused with volatile corrosion inhibitors, these papers are designed to shield metals from corrosive agents actively. As the paper comes into contact with the metal product, it releases the VCI compounds, protecting it against corrosion. They’re particularly handy for wrapping individual components or interleaving between metal sheets or parts.

VCI Foams and Emitters: VCI foams are often used to cushion and protect sensitive equipment during transport. Besides their protective padding function, they continuously release VCIs to safeguard the metal parts from corrosion. Emitters, on the other hand, are compact devices or sachets filled with concentrated VCI compounds. They’re placed inside packaging to protect electronics, machinery parts, or any other metallic items from corrosion.

Choosing the Right VCI Packaging: The right packaging is crucial for effective protection.

- Type of Metal: Different metals might require different VCI formulations.

- Duration of Protection Needed: Some VCIs are designed for short-term protection, while others offer long-term shielding.

- Environmental Conditions: If the product is exposed to harsh conditions, like extreme humidity or salinity, a stronger VCI protection might be required.

- Size and Shape of the Product: Larger or more intricately shaped products might benefit more from films or bags, while smaller components could be wrapped in VCI papers.

- Sustainability Concerns: Opt for VCI materials that align with the company’s environmental sustainability goals.

Best Practices During Packaging

The effectiveness of volatile corrosion inhibitors (VCI) in packaging depends on the proper handling, storage, and application of these materials. Following best practices ensures that the stored or transported items remain pristine, free from the detrimental effects of corrosion.

Proper Storage of VCI Materials:

- Environment: Store VCI materials in a cool, dry place, away from direct sunlight. Prolonged exposure to high temperatures or UV light can degrade the VCI compounds, reducing their efficacy.

- Sealed Packaging: Ensure VCI materials, especially films and papers, remain in their original sealed packaging until use. This prevents premature vaporization of the VCI compounds.

- Avoid Contamination: Keep VCI materials away from contaminants, such as oils, solvents, or other chemicals, which might interfere with their protective properties.

Handling and Application Tips:

- Gloves are Essential: Always handle VCI materials with clean gloves. Oils and contaminants from the hands can reduce the efficacy of the VCI compounds.

- Limit Exposure Time: Once VCI packaging is opened, use it promptly. Extended exposure to the ambient environment can lead to the loss of volatile inhibitors.

- Avoid Over-stretching: If using VCI films or bags, avoid over-stretching, which can thin out the material, potentially reducing its effectiveness.

- Seal Properly: Ensure that VCI bags or enclosures are adequately sealed to maintain a controlled environment, maximizing the protection offered.

Ensuring Adequate Coverage and Protection:

- Complete Coverage: Ensure the VCI material completely envelops the protected item. Any exposed areas can become potential sites for corrosion.

- Consider the Product’s Shape: For intricately shaped or coiled products, consider using VCI foams or emitters to ensure that even hard-to-reach areas receive adequate protection.

- Refreshment: If storing items for an extended period, periodically check the potency of the VCI protection. Depending on the storage conditions, you might need to refresh or replace the VCI materials.

- Pair with Desiccants: For added protection, especially in humid environments, consider using desiccants packs alongside VCI packaging. This ensures both moisture absorption and corrosion protection.

Conclusion

VCIs offer a protective shield against corrosive agents and ensure that products maintain their functionality and appearance. During storage, transit, or prolonged exposure to varying conditions, VCIs consistently demonstrate their pivotal role in safeguarding materials. Humi Pak provides an extensive selection of VCI anti-corrosion packaging solutions in Malaysia. Please contact us for detailed information or to schedule an appointment with our packaging engineers.