How to Prevent Rust with VCI

According to the International Energy Agency (IEA), OPEC oil supply was at an all-time high during September 2016, while growth in oil demand slumped to a four-year low in the same period. Expected growth for global oil throughput in 2016 year-on-year is at a mere 220kb/d, the lowest in more than a decade, not including the last economic downturn.

The impact of the oil market slump has inevitably caused million-dollar equipment to be left idle for an indeterminate period. Left unused and under environmental stresses, the once-running 24-hours-a-day stacked oil rigs may start to corrode, hindering operational use once the market rebounds!

Protection from corrosion can be as simple and cost-effective as using Volatile Corrosion Inhibitors (VCIs) to safeguard the equipment’s internal components against the effects of moisture, salt, and other contaminants. Using VCI products to avoid corroded engines and pumps or clogged fuel pipes incurs less downtime and cost than replacement.

Effects of Rust on Metals

Rust is a common term for a series of iron oxides. This reddish-brown compound forms when iron reacts with oxygen in the presence of water or moisture. The most commonly referred form of rust is iron(III) oxide (Fe₂O₃·nH₂O). It’s not just rain and puddles that pose a threat; even high humidity can facilitate rust formation. It can compromise the strength, functionality, and longevity of metal items and structures, posing safety and economic challenges. Preventing rust, therefore, is crucial in many industrial and domestic settings.

- Structural Weakness: Rust can significantly weaken iron and its alloys. As rust forms, it can expand and displace the underlying metal, leading to a loss of structural integrity. Over time, items or structures made of these metals can fail under loads or stresses that they were initially designed to handle.

- Economic Impact: Rusting metals can have significant economic implications. Equipment or infrastructure affected by rust often requires replacement or costly repairs. In industries, rusted machinery can lead to downtime and lost productivity.

- Aesthetic Degradation: Rust can mar the appearance of metal objects or structures. This is especially problematic for items with important aesthetics, such as vehicles, architectural features, and consumer goods.

- Functional Failures: Moving parts in machinery can seize or become less efficient when affected by rust. For example, rust on a hinge can make a door hard to open, or rust on a vehicle’s brake components can compromise safety.

- Reduced Conductivity: For electrical systems, rust can reduce the conductivity of components, leading to inefficiencies or failures.

- Chemical Changes: As metals corrode, they can produce other compounds which might be harmful or undesirable in certain settings. For instance, rust can lead to the formation of acids, which might further damage the metal or surrounding materials.

Understanding Volatile Corrosion Inhibitors

Volatile Corrosion Inhibitors (VCIs) are a class of chemical compounds that, when released into the atmosphere, protect metal surfaces from corrosion by forming a thin, protective layer on the metal. These compounds are called “volatile” because they can evaporate from a source (like a VCI-impregnated paper or plastic film) and then condense on the surface of the metal, protecting corrosive elements.

VCIs work by first evaporating from their source. Once in the vapour phase, they travel and distribute uniformly within a confined space until they come into contact with a metal surface. VCIs condense and form a very thin, invisible molecular layer upon contact. This protective layer inhibits the electrochemical processes that lead to corrosion, preventing moisture and other corrosive agents from interacting with the metal. The layer is often only a few molecules thick, but it is sufficient to disrupt the chain reactions that cause corrosion.

Types of VCI Packaging Solutions

Types of VCI Packaging Solutions

By selecting the appropriate VCI packaging solution based on the type of metal, storage condition, and duration, industries can ensure optimal corrosion protection for their products and assets.

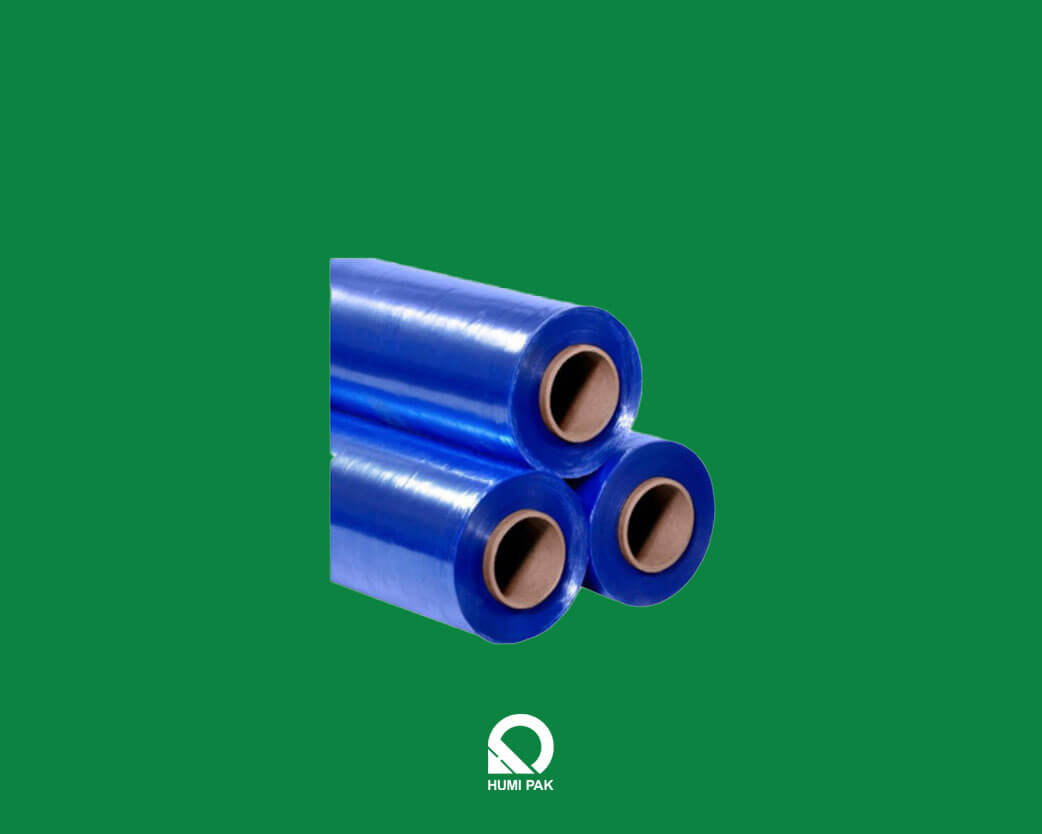

VCI Films and Bags

VCI films and bags are plastic, typically polyethene, impregnated or coated with VCI compounds. When these films or bags are placed around metal parts, the VCI compounds slowly release from the plastic, evaporating and forming a protective molecular layer on the metal surfaces within the wrapped space.

Common Usage Scenarios:

- Shipping and Storage: VCI bags are often used to package metal parts for long-term storage or during transportation to protect against corrosion that might occur due to changing environmental conditions.

- Manufacturing: After manufacturing or machining operations, metal parts can be wrapped in VCI films to protect them until they’re used or shipped.

- Electronics: VCI films can be used to wrap electronic components, preventing corrosion of metal contacts and leads.

VCI Papers

VCI papers are sheets or rolls soaked in or coated with VCI compounds. The paper acts as a carrier for the VCI, releasing it over time to protect nearby metal objects.

Different Types and Their Applications:

- Kraft VCI Paper: Made from natural kraft paper saturated with VCIs, it’s commonly used for wrapping ferrous metals like iron and steel.

- Poly-Coated VCI Paper: This paper has a layer of plastic coating, providing additional moisture barrier properties. It’s suitable for metals stored in especially humid environments.

- Wax-Coated VCI Paper: Offers a layer of wax for added moisture resistance and is often used with other packaging materials for added protection.

- Creped VCI Paper: Features a creped or wrinkled texture, stretching and fitting snugly around irregularly shaped objects.

- Speciality Papers: Designed for specific metals such as copper, silver, or aluminium, these papers have VCIs tailored for the unique corrosion prevention needs of each metal type.

VCI Emitters and Diffusers

VCI emitters and diffusers are designed to release VCIs into enclosed spaces. They often come in small, permeable containers or pouches filled with concentrated VCI compounds.

Products Designed for Enclosed Spaces:

- Capsules or Pots: These are small containers filled with VCIs and ideal for toolboxes, electrical cabinets, or other small enclosed spaces.

- Foam Pads: These pads, soaked in VCI compounds, can be placed in packages, containers, or storage bins to protect a range of metal items.

- VCI Pouches: These are sachet-like packets filled with VCI crystals or powders. They’re suitable for larger storage boxes or shipping crates.

- VCI Diffuser Units: These are designed for large spaces like storage tanks or shipping containers. They release substantial VCI to protect big and often valuable equipment.

Benefits of Using VCIs for Rust Prevention

VCIs offer a trifecta of benefits in rust prevention: extended protection, cost-effectiveness, and a lesser environmental footprint. As industries worldwide become more eco-conscious, the shift towards solutions like VCIs that offer both performance and sustainability is inevitable.

Long-Term Protection

The benefits of using Volatile Corrosion Inhibitors (VCIs) for rust prevention are multifaceted, offering distinct advantages over traditional corrosion prevention methods. One of the most notable benefits of VCIs is their capacity to provide long-term protection against rust.

The continuous release and self-replenishing nature of VCIs mean they constantly vaporize and redeposit on metal surfaces, ensuring consistent coverage and protection, especially in sealed environments where the vapours can fully saturate the space. This makes them ideal for protecting metals over extended periods, often ranging from several months to years, based on the application and storage circumstances.

Cost-Effectiveness

In terms of economic advantages, VCIs are notably cost-effective. Their straightforward application, whether through films, papers, or emitters, often translates to reduced labour costs.

Additionally, unlike conventional rust prevention treatments, there’s no need to remove VCIs before the metal part is processed or used, leading to time and cost savings. This prevention also implies a decrease in the need for costly repairs or replacements of corroded components, further enhancing the lifespan of machinery and parts.

Environmentally Friendly Options

On the environmental front, VCIs stand out for their eco-friendly attributes. Traditional rust preventatives may contain hazardous ingredients that result in harmful waste, whereas many VCIs, especially those in paper or film forms, minimize this environmental burden. Water-based VCIs signify a move towards products with reduced environmental consequences compared to their solvent-based counterparts.

Moreover, VCI packaging materials’ recyclability and typically lower VOC emissions contribute to a decreased environmental footprint. Some contemporary VCI products even incorporate biodegradable or sustainably sourced components, emphasizing their eco-conscious design.

Conclusion

Volatile corrosion inhibitors (VCIs) play a pivotal role in safeguarding metals against the detrimental effects of rust and corrosion. Their unique mechanism of releasing protective compounds forming molecular barriers on metal surfaces offers immediate protection against environmental factors. It ensures extended protection, reducing the need for frequent maintenance or reapplications.

This proactive approach to rust prevention translates directly into the longevity of metals, ensuring that they retain their structural integrity, functionality, and aesthetic appeal over time. Humi Pak offers an extensive selection of advanced volatile corrosion inhibitor solutions tailored to your needs. Reach out to our packaging engineers for more insights.