How to Use Moisture Barrier Packaging to Protect Products

Packaging plays a significant role in preservation of products, safeguarding items from external factors and ensuring they reach consumers in optimal condition. Effective packaging serves dual purposes. Firstly, it’s a protective barrier against physical, chemical, and environmental threats. Secondly, it’s a communication tool, conveying essential information about the product within.

Among the challenges faced in packaging, moisture stands out. Whether it’s food getting spoiled, electronics malfunctioning, or medicines losing efficacy, moisture is often the cause. Its infiltration can reduce product lifespan, affect brand reputation, and ultimately lead to economic losses. Recognizing and addressing this issue is pivotal, especially with solutions like moisture barrier packaging.

What is Moisture Barrier Packaging?

As products travel from manufacturers, they face a host of environmental factors. One of the most significant threats they encounter is moisture, which can compromise product quality and shelf life. Moisture barrier packaging is designed to restrict the passage of moisture and protect the contents from potential damage caused by humidity, liquid spills, or other moisture sources.

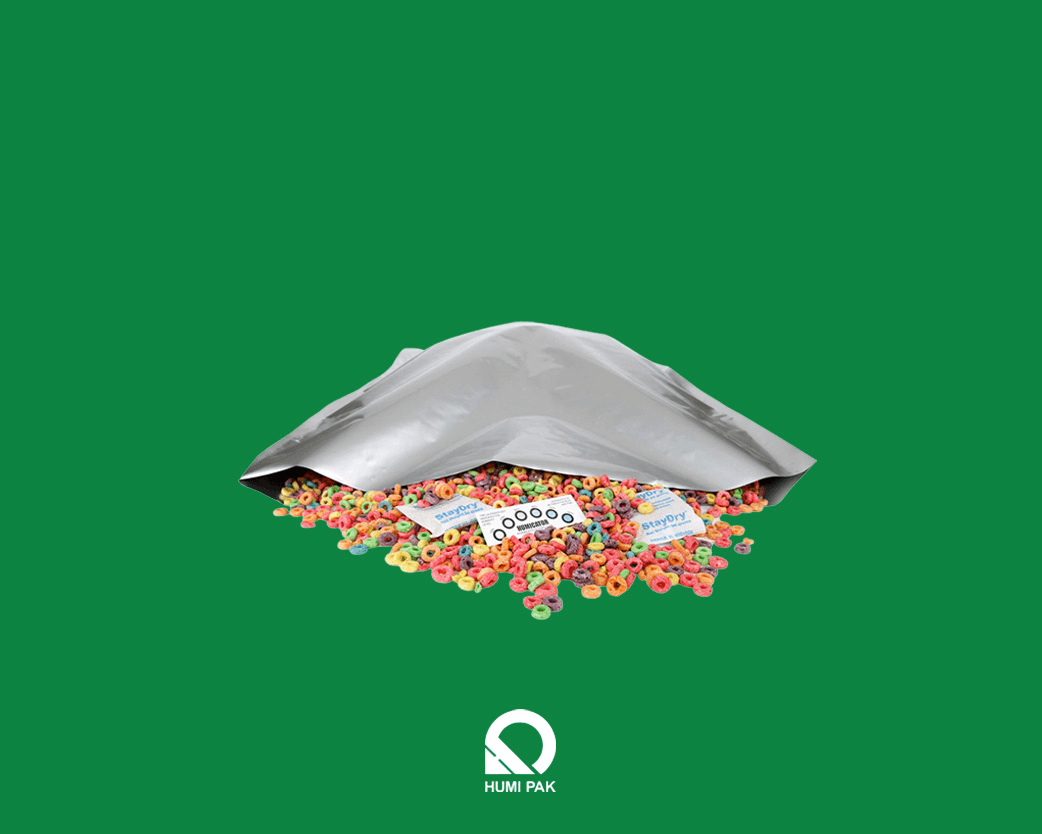

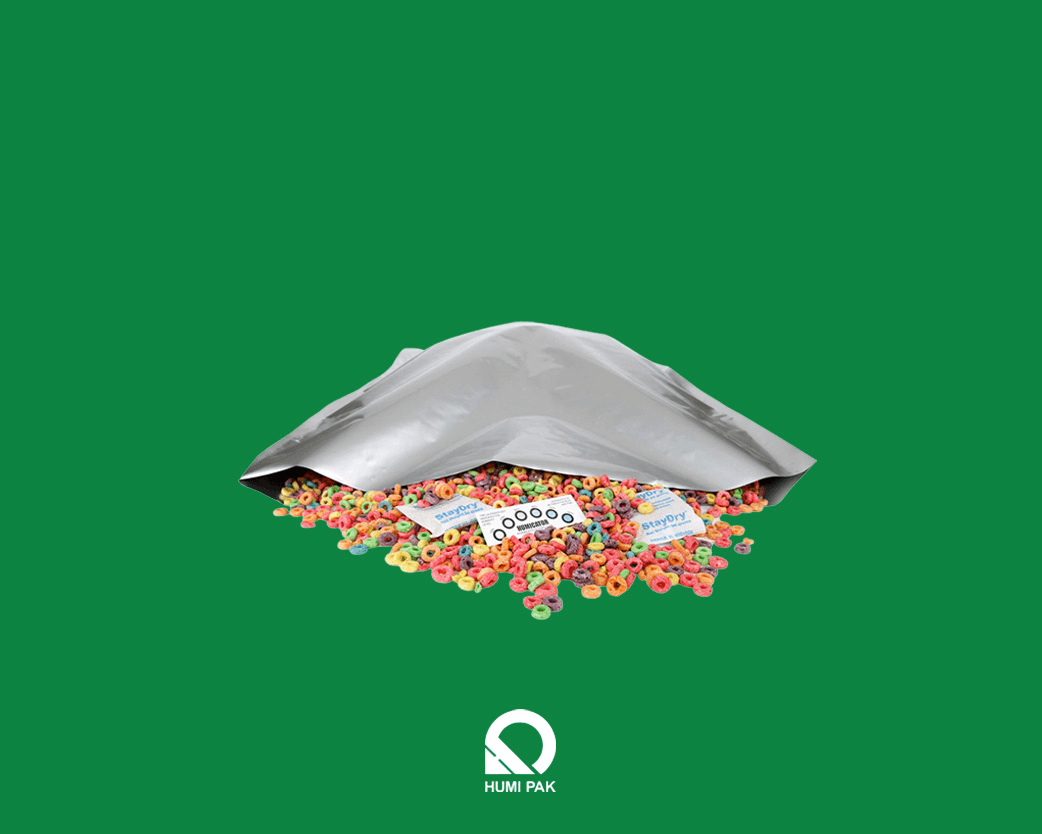

These packaging materials often have multiple layers or coatings, each serving to prevent the ingress of water vapour. Moisture barrier packaging relies on materials repelling or resisting moisture. Common materials like foil or metallized films serve as protection against water vapour.

These materials have low water vapour transmission rates (WVTR), allowing minimal moisture. Furthermore, some moisture barrier packaging includes desiccants, which actively absorb any moisture that might have been trapped during the packaging process. The combination of these moisture-resistant materials and the active absorption of desiccants ensures that the internal environment remains dry and stable, safeguarding the product’s integrity.

Types of Packaging Materials

Each material has unique properties, making it suitable for specific applications and product types. Each of these materials and solutions offers unique advantages, and their use depends on the specific needs of the product and the desired level of protection.

Foil and Metallized Films

Comprising thin layers of metal, typically aluminium, bonded to a substrate such as plastic or paper, they create an almost impenetrable shield against moisture. Two such materials are moisture barrier bags and reinforced aluminium foils.

This metal layer, by nature, is non-permeable, making it an exceptional choice for items that need heightened protection against humidity, like dried foods or sensitive electronics. These materials are especially prevalent in snack bags, pharmaceutical blister packs, and pouches designed to store dried goods.

Coated Films

These plastic films have undergone a treatment process where a protective layer or coating is applied to boost their barrier attributes. Materials such as polyvinylidene chloride (PVDC) or ethylene vinyl alcohol (EVOH) are common choices for these coatings.

The primary advantage of coated films lies in their adaptability; they are flexible and can be customized to align with specific product requirements. This adaptability and solid moisture resistance make them a preferred choice for packaging fresh produce, meats, and dairy products.

Vacuum Seal Bags

These bags, crafted from a resilient plastic film, house the product and have their internal air evacuated to create a vacuum before being sealed by vacuum sealing machines. By doing so, the potential for moisture contamination is significantly diminished.

A benefit to this approach is the space efficiency; with the air removed, the product becomes more compact, facilitating easier storage. The utility of vacuum seal bags is evident in their widespread usage across various sectors; they are used for preserving foods like meats and cheeses and are also handy for storing items like clothing or bedding to shield them from moisture and pests.

Desiccant Packs and Inserts

Desiccants are designed to absorb moisture from their immediate environment, working to keep the surroundings dry. They are often encapsulated in small sachets or packs and then integrated into the product packaging. Their value is especially pronounced for products vulnerable to even trace amounts of moisture.

Whether it’s a bottle of pills, a box containing electronics, or a food product that could spoil with moisture, these packs serve as an extra layer of protection. They are particularly effective when used with other barrier materials, ensuring that any moisture trapped during packaging is absorbed.

Benefits of Using Moisture Barrier Packaging

Incorporating moisture barrier packaging is not just about maintaining the physical state of a product; it’s about upholding a brand’s promise to its consumers and ensuring that products reach them in the best possible condition.

Prolonged Product Shelf Life

One of the most immediate and tangible benefits of using moisture barrier packaging is extending a product’s shelf life. Moisture can accelerate the degradation of many products, from food to electronics. By effectively sealing out moisture, products remain fresh and functional for extended periods. This means less waste for consumers and ensures that products stay in saleable condition for longer, reducing the potential for unsold or returned inventory for businesses.

Prevention of Product Damage or Spoilage

Moisture can be a silent destroyer. Its impact can be diverse and devastating, from causing electronics to short circuits to being the catalyst for mould growth in food items. The risks associated with such damages or spoilage are drastically reduced with the use of moisture barrier packaging. This means fewer returns and complaints for businesses and consumers; it translates to safer and more reliable products.

Maintains Product Quality and Integrity

Beyond just preventing spoilage or damage, moisture barrier packaging plays a pivotal role in preserving the inherent quality of products. For instance, a snack’s crispness, the medication’s efficacy, or the semiconductor’s performance can all be compromised by moisture. By using appropriate moisture barrier solutions, manufacturers ensure that consumers experience their products as intended, in their best and most effective form.

Cost Savings in the Long Run

While the initial investment in moisture barrier packaging might be higher than conventional packaging, its long-term savings often outweigh the costs. Businesses can save significantly on potential losses by reducing product spoilage, returns, and complaints. Additionally, by extending product shelf life, there’s a decrease in wastage, leading to more efficient inventory management and reduced production costs.

Considerations When Choosing Moisture Barrier Packaging

Selecting the right moisture barrier packaging requires a thorough understanding of the product, its journey, and the external factors it will encounter. Manufacturers can ensure optimal protection while addressing cost and environmental concerns with careful consideration and analysis.

Product Sensitivity to Moisture

Before selecting the appropriate moisture barrier packaging, it’s crucial to understand the product’s sensitivity to moisture. Some products might degrade rapidly even with minimal moisture exposure, while others may only require protection in extreme conditions.

For example, certain electronics or pharmaceuticals might be highly sensitive, necessitating top-tier moisture barriers. In contrast, some food products might only require moderate protection. Understanding the degree of sensitivity helps choose a packaging solution that’s neither overkill nor insufficient.

Storage and Shipping Conditions

The conditions under which the product will be stored and transported play a significant role in determining the type of moisture barrier packaging required. Will the product be stored in a humid region or shipped across various climates?

Will it be subjected to drastic temperature changes? These factors can affect the efficacy of the moisture barrier. Products exposed to fluctuating conditions might require more robust protection than those stored in a controlled environment.

Environmental and Sustainability Concerns

With increasing emphasis on sustainable practices and reducing environmental impact, it’s essential to consider the ecological footprint of the chosen packaging. Some moisture barrier materials might be non-biodegradable or challenging to recycle.

Manufacturers must weigh the need for effective moisture protection against environmental concerns. Exploring innovative, eco-friendly barrier solutions that don’t compromise on protection is a worthy consideration for brands looking to balance functionality with sustainability.

Cost vs. Benefits Analysis

While the primary aim is to protect the product, keeping the overall costs in check is also essential. Investing in the most advanced moisture barrier packaging might be the best approach. Still, if the costs significantly outweigh the benefits, it may not be a viable option, especially for products with thin profit margins.

Manufacturers should conduct a thorough cost-benefit analysis, considering potential savings from reduced spoilage and returns against the initial investment in the packaging. This ensures a balanced approach where product protection is achieved without straining the budget.

Conclusion

Moisture barrier packaging helps with product preservation, integrity, and longevity. The adverse effects of moisture on many products, from food items to electronics, underscore the need for effective moisture protection. As consumer expectations rise and the complexities of global logistics become more pronounced, ensuring products remain in optimal condition during transit and storage is essential.

Moisture barrier packaging is essential in maintaining product integrity. Humi Pak specializes in these protective solutions, offering tailored answers to diverse packaging challenges. For more information or to discuss specific requirements, our packaging engineers are available to assist.