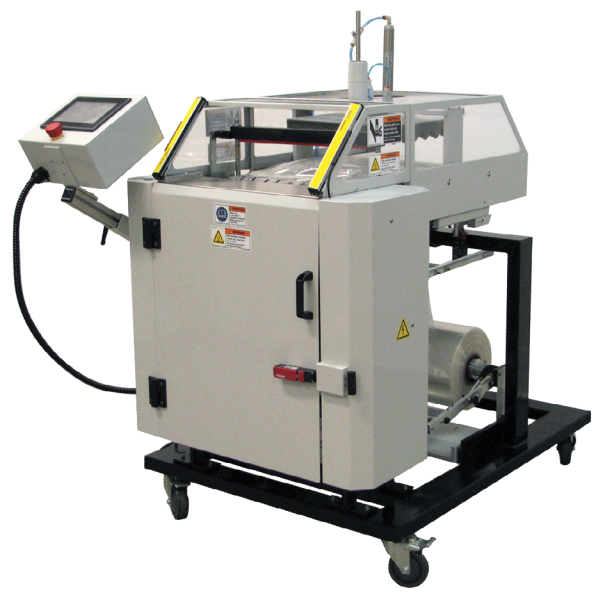

Auto Bag Magnum Horizontal Automatic Bagger

Auto bag magnum horizontal bagger is a packaging machine designed for large, heavy products or applications requiring special handling. It has a horizontal loading configuration, making it ideal for extensive bag packaging.

High-Speed Performance

Depending on the specific requirements, this auto bagger operates with pre-opened bags on a roll or poly tubing. It can achieve a rate of up to 70 bags per minute with pre-opened bags and 40 bags per minute with poly tubing. Using poly tubing offers the advantage of lower material and inventory costs and the ability to adjust bag lengths for accurate sizing quickly.

The bag-filling machine is user-friendly and easy to operate. It incorporates robotics and other automatic infeed devices to streamline the fitting of bulky products into the bags. It also features a built-in interface for seamless integration.

Efficient Packaging Solution

The auto bagger offers optional features such as a thermal transfer printer label applicator, which can print text, barcodes, or graphics directly onto the bag. It can be customised with various options, including a hole punch, a larger seal bar, and a light curtain to suit specific packaging applications.

- Heavy-duty packaging for large, heavy products

- Horizontal loading configuration for extensive bag packaging

- Option for pre-opened bags on a roll or poly tubing

- High-speed operation: Up to 70 bags per minute (pre-opened bags), 40 bags per minute (poly tubing)

- Cost-effective poly tubing for lower material and inventory costs

- Adjustable bag lengths for accurate sizing

- User-friendly and easy to operate

- Robotics and automatic infeed devices for streamlined bag filling

- Built-in interface for seamless integration

- Optional thermal transfer printer label applicator for direct bag printing

- Customisable with features like hole punch, larger seal bar, and light curtain

- Speed: Up to 40 bags/min with poly tubing, 70 bags/min with bags on a roll (dry cycle)

- Bag Width: 2″ – 13″ (51mm – 331mm)

- Bag Length: 4″ – 96″ (102mm x 2440mm)

- Bag Thickness: 1mil – 5mil

- Seal Width: 1/8″

- Electrical Requirement: 120v, 16a, 50/60hz

- Air Requirement: 80psi @ 5 CFM

- Dimensions (W x D x H): 38″ x 45″ x 45″ (965mm x 1143mm x 1143mm)

- Weight: 520 lbs (236kg)

- Warranty: 1 year limited warranty, extendable up to 5 years

Autobag Magnum Horizontal Automatic Bagger Product Brochure - Humi Pak Malaysia: Download