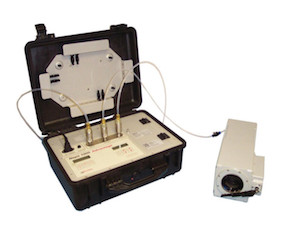

Nitrogen Enhanced Purging System 1000 Advantage

Nitrogen Enhanced Purging System (NEPS) utilises dry nitrogen to remove humidity and oxygen inhibition by purging electronics such as optical equipment and high-voltage laser systems. This purging process effectively mitigates the presence of hygroscopic moisture, which can cause long-term damage to electronic components.

Effective Moisture And Optimal Humidity Control

The NEPS is a self-contained nitrogen purging system that ensures optimal humidity control. To purge the equipment, connect the dry gas source to the equipment port and inlet connection. Gas distribution and control are efficiently managed through a single pipe connection.

During the depression phase, the purge gas is isolated, allowing the internal gas to pass through a dew point sensor for accurate measurement and continuous monitoring. Compared to conventional purging methods, the NEPS prevents the gas from following the path of least resistance, often leading to pockets of unconditioned gas within the equipment.

Gas and Leak Testing for Equipment Integrity

The purging system offers selectable programming options, enabling users to view process control values, dew point measurements (Celsius or Fahrenheit), and pressures (Kpa or psi).

Before the purging operation, gas and leak testing can be performed to verify the integrity of the gas supply and the equipment. The NEPS1000 is compatible with international voltages ranging from 100 to 230 VAC at 50-60 Hz, making it well-suited for diverse applications. These include storage containers, switchgear, underwater equipment, and surveillance devices.

- Easy to Use Single Connection Purging

- Dew Point and Pressure Readout

- Remote Dew Point Sensing Option

- Portable and Robust

- User Programmable

- Automatic Purging Operation

- Dew Point Stat Gas Control

- Dew Point Display from +20ºC to -80ºC

- Maintainable Online

- NATO Approved

| Useable Gases | Air, Nitrogen, SF6, Helium, Argon |

|---|---|

| Selectable Pressure Ranges | 10.3 Kpa (1.5 psi) 17.2 Kpa (2.5 psi) 34.4 Kpa (5.0 psi) |

| Display Range Pressure | 0 to 34.4 Kpa (0-5.0 psi) |

| Display Range Dewpoint | (Selectable) +20ºC to –80ºC dewpoint +68ºF to –94ºF dewpoint |

Resolution | 0.1ºC dewpoint |

Accuracy | +/- 2ºC dewpoint |

| Data Output Pressure | 0 – 5 Volts |

| Data Output Dewpoint | 0 – 5 Volts |

Power | 100-230 volt 50 hz – 60 hz |

Power Consumption | 3 amps |

Dimensions | 490W x 425D x 190H (closed) |

Weight | 12 kilograms |

Ingress Protection | IP54 (Closed Case) |

Operating Temp | -10ºC to +50ºC |

Storage Temp | -50ºC to + 65ºC |

Proof Pressure | input 137 Kpa (20 PSI) |

Flowrate (typical) | 20 litres per minute |

Nitrogen Enhanced Purging System 1000 Advantage Product Brochure - Humi Pak Malaysia: Download