Ethylene Pallet Covers

Ethylene absorbent pallet covers protect perishable products during transportation and storage. Ethylene can accelerate the ripening process and contribute to the decay of sensitive produce, leading to reduced shelf life and quality.

The absorbers prevent the negative effects of ethylene gas, a natural plant hormone released by fruits, vegetables, and flowers as they ripen and age.

Prevent Ethylene Gas Effects

Ethylene pallet covers consist of a plastic film impregnated with an ethylene-absorbent material. This absorbent material traps and removes ethylene gas from the surrounding environment. By reducing the ethylene concentration, these covers can help slow the ripening process and extend the shelf life of the perishable goods.

The ethylene absorber covers can be placed over palletized products or individual containers, such as crates or boxes containing fruits, vegetables, or flowers. They create a barrier that prevents ethylene from reaching the product, effectively reducing the exposure and maintaining the freshness of the items during transportation and storage.

Preserve Quality and Minimize Waste

Ethylene pallet covers can be used in the agriculture, horticulture, and food industries, where preserving the quality and extending the shelf life of perishable goods is crucial.

They are particularly beneficial for long-distance transportation, international shipping, and storage in warehouses or cold storage facilities. By controlling ethylene levels, these covers can help minimize waste, improve product quality and enhance overall supply chain efficiency.

- Ethylene gas removal

- Extended shelf life

- Contaminant elimination

- Porous paper design

- Faster reaction speed

- Water-resistant composition

- Plastic barrier protection

- Cost-effective transportation

- Ripening process control

- Customisable sizes

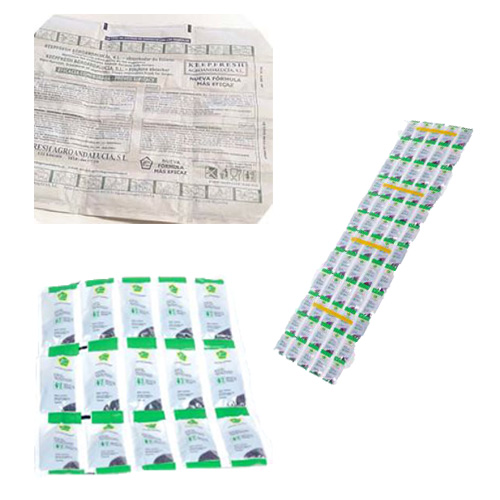

Ethylene Absorbent Pallet Covers (General)

- For applications that require a greater amount of granules

- Used as replacement of the tube filters in reefer containers

- For controlled atmosphere containers and air freight containers

- Used for products that emit high levels of ethylene (Apples, mangoes, avocados and kiwis)

Ethylene Absorbent Pallet Covers (Pineapples & Berries)

- For long-distance transportation

- For protecting pineapple and different berries

- Used as replacement of the tube filters in reefer containers

- For fruits with lower levels of emissions but a higher need for air filtration

Ethylene Absorbent Pallet Covers (Bananas and Plantains)

- It does not interfere with the artificial ripening process

- Used as replacement of the tube filters in reefer containers

- Recommended for protecting bananas and plantains without Banavac bags

Ethylene Absorbent Pallet Covers (Long-term preservation)

- For fruits that emit high levels of ethylene

- For the long-term preservation of fruits like apples and pear

Ethylene Pallet Covers Product Brochure: Download