Features of The Automatic Bagging Machine

Historically, the packaging industry relied heavily on manual labour. Workers filled, weighed, and sealed bags by hand—a time-consuming process often resulting in inconsistencies. As industries grew and the demand for quicker, more efficient processes intensified, automatic machines emerged.

By automating most of the process, these machines ensured greater accuracy, faster production rates, and reduced human error. Today’s automatic bagging machines, equipped with advanced sensors and programmable controls, cater to the demands of the modern packaging industry.

Understanding Automatic Bagging Machines

Autobag Bagging machines, fundamental to the packaging industry, are specialized equipment designed to fill and seal bags with various products, ranging from food grains to powdered substances and even liquid products. These machines ensure that products are packaged securely and efficiently, enabling businesses to distribute their goods consistently and reliably. The bagging machines’ accuracy, speed, and reliability directly affect production rates, cost efficiency, and product quality.

Fundamental Components

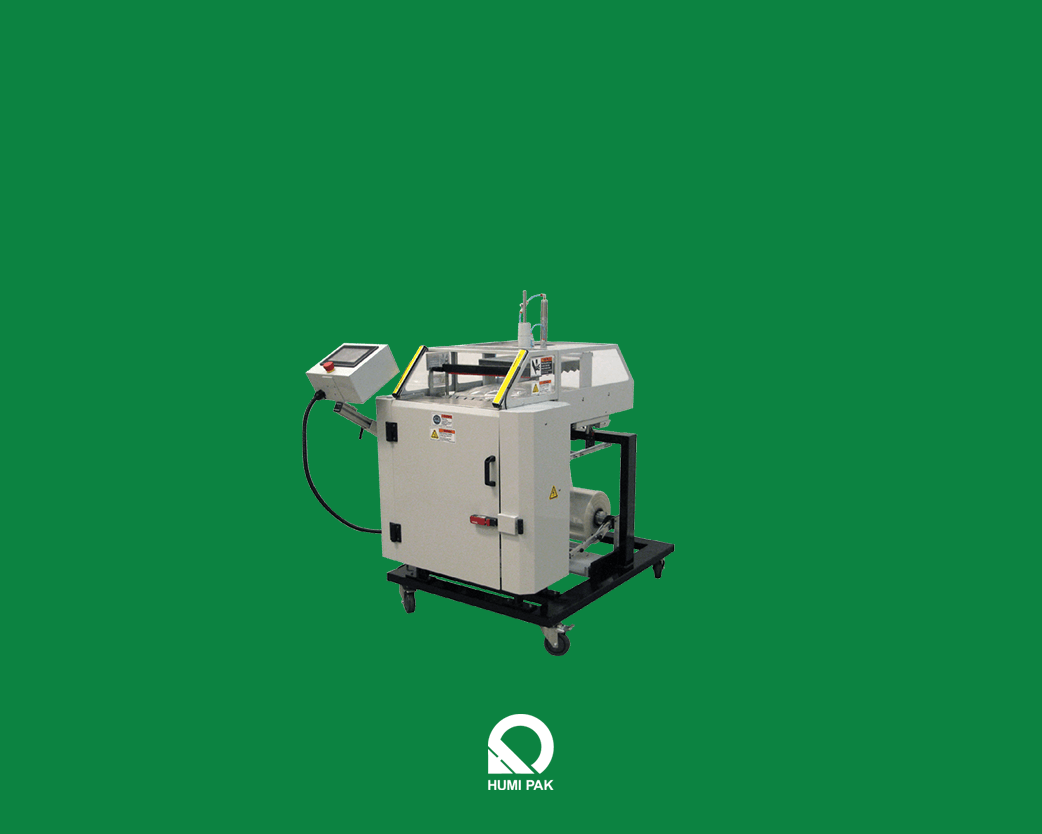

Control Panel & User Interface: This component allows operators to dictate machine operations, select specific functions, and monitor performance metrics. Modern control panels are often equipped with touchscreen displays, making it intuitive to set up and adjust the machine’s parameters. The control panel is the central hub where the entire machine’s operation is directed and controlled.

Feeding Mechanism: Depending on the material to be bagged, this can be a gravity feed, a screw drive, a vibratory feed, or even a liquid pump system. The primary purpose is to ensure that the correct quantity of product is dispensed into each bag, and the design varies based on the material’s nature (solid, powder, liquid).

Sealing and Cutting Units: These components ensure that each bag is hermetically sealed to protect the contents and maintain product quality. The sealing mechanism typically uses heat or ultrasonic methods to fuse the bag’s edges, while the cutting units trim excess material or separate individual bags from a continuous roll. Precision and speed are paramount here to maintain efficiency and product integrity.

Conveyor System: The conveyor system of an automatic bagging machine is designed to move bags seamlessly through the various stages of the packaging process. From the initial filling stage to the final sealing and discharge, the conveyor system ensures that each bag is accurately positioned and transported without manual intervention. Depending on the machine’s design and the bags being processed, these systems can be belt-driven, chain-driven, or even vacuum suction.

Weighing and Measurement Module: Accuracy is crucial in packaging, and the weighing and measurement module ensures that each bag contains the right amount of product. Bags are weighed before or after the filling process to verify that they meet the set requirements. If discrepancies are detected, adjustments are made automatically, or the bag is flagged for manual inspection in some advanced systems. This module integrates seamlessly with the control panel, feeding data to the user interface and ensuring consistent packaging accuracy throughout the operation.

Key Features and Benefits

High-Speed Packaging: Bagging machines are engineered for speed, capable of processing thousands of bags in an hour. This rapid processing capacity allows industries to meet high-volume demands, increasing productivity and meeting market needs more effectively.

Consistent Bag Quality and Seal Integrity: These machines are equipped with precision tools and sensors that ensure each bag is of consistent quality, with robust and secure seals. A dependable seal ensures the longevity and safety of the product, reducing potential returns or customer complaints. Consistency in quality also enhances brand reputation.

Versatility in Bag Types and Sizes: Modern packaging machines can accommodate various bag materials, types, and sizes, often with quick-change settings. This versatility means that manufacturers can diversify their product range without needing to invest in multiple machines, leading to cost savings and increased flexibility in production.

Integrated Diagnostic and Error-Handling Systems: Advanced machines have built-in diagnostic tools that detect and sometimes automatically rectify issues. Early error detection reduces downtime and potential damage to the machine. Automated error-handling systems also ensure consistent output and reduce manual monitoring requirements.

Reduced Wastage and Material Consumption: Precise measurement systems and efficient bag usage algorithms ensure optimal use of materials. Businesses can minimize waste, leading to direct cost savings and a reduced environmental footprint. Efficient material usage also means less frequent reordering of supplies.

User-friendly Operation and Maintenance: The user interfaces of these machines are designed to be intuitive, often with touchscreen controls and clear visual indicators. Maintenance procedures are straightforward, with many machines offering easy access to components. Ease of use reduces the learning curve for new operators and reduces the risk of human error. Simplified maintenance ensures machines have a longer operational lifespan and reduces potential downtime.

Advanced Technological Integrations

Touchscreen and Programmable Logic Controllers (PLCs): Bagging machines often come with touchscreen interfaces that interact directly with Programmable Logic Controllers (PLCs), providing real-time operational feedback and precise control. Touchscreen interfaces offer a more intuitive user experience, enabling operators to adjust quickly. Meanwhile, PLCs provide reliable, consistent, and automated control of the machine’s functions, improving operational efficiency and reducing human error.

Internet of Things (IoT) and Remote Monitoring: Many bagging machines are now IoT-enabled, allowing them to connect to networks and offer remote monitoring capabilities. This connectivity ensures that machine operations can be overseen from distant locations, offering flexibility in monitoring and management. It also facilitates prompt troubleshooting and potential preventive maintenance, reducing downtimes.

Automatic Adjustments and Calibration: The machines’ advanced sensors and feedback systems allow for automatic adjustments and calibrations in real-time. This ensures that the machine operates at optimal settings, adapting to input or environmental conditions variations. It results in consistent product quality and reduces the need for manual recalibrations.

Integrated Barcode and Labeling Systems: Integrated systems directly print and apply barcodes, QR codes, or other labels onto the bags. This integration streamlines the packaging process, ensuring products are ready for distribution, tracking, or retail immediately after bagging. It reduces the need for secondary labelling processes and enhances traceability.

Real-time Data Collection and Analytics: Collecting data in real-time on various operational metrics, such as throughput, error rates, and efficiency. This data, when analyzed, provides valuable insights into machine performance, allowing businesses to optimize operations, predict maintenance needs, and make informed decisions on process improvements.

Future Trends in Bagging Technology

Integration with Robotics: The future of automatic bagging will likely see increased collaboration between bagging machines and advanced robotics. With their precision and range of motion, robots can perform tasks such as picking, placing, and even intricate product arrangement within bags. Integrating robotics will further streamline the bagging process, reduce the need for human intervention in challenging or repetitive tasks, and increase the overall efficiency and speed of the packaging process.

AI-Powered Predictive Maintenance: Artificial Intelligence (AI) is set to play a pivotal role in future bagging machines. By analyzing vast amounts of operational data, AI can predict when a machine component might fail or when maintenance is due. Predictive maintenance can significantly reduce unplanned downtimes, extending the machine’s lifespan and ensuring consistent production schedules. This leads to cost savings and increased operational reliability.

Sustainable and Biodegradable Bagging Solutions: As environmental concerns continue to drive industry trends, there will be a greater push towards bagging solutions that utilize sustainable or biodegradable materials. Using sustainable materials not only reduces the environmental footprint of packaging but also resonates with eco-conscious consumers. Companies that adopt such solutions can improve their brand image and cater to a growing market segment that values sustainability.

Customization and Personalization Options: Future bagging technologies will likely offer more customization options, such as on-the-fly printing of custom designs, logos, or personalized messages directly on the bags. Such features allow businesses to differentiate their products, catering to niche audiences or offering specialized branding for events or promotions. This enhances brand visibility and offers unique marketing opportunities directly from the packaging line.

Conclusion

From basic mechanisms to today’s high-tech solutions, these machines have continually adapted to meet the demands of efficiency, precision, and sustainability. As we look ahead, integrating robotics, AI, and environmentally-conscious materials will further refine the bagging process. For businesses, understanding and adapting to these trends is crucial, not just for operational efficiency but also for long-term competitiveness.

Humi Pak offers an extensive selection of automatic packaging machines tailored to meet various packaging needs. Reach out to us to schedule a consultation with our packaging engineers. Beyond supplying equipment, we also offer comprehensive training and maintenance services to meet your packaging requirements.