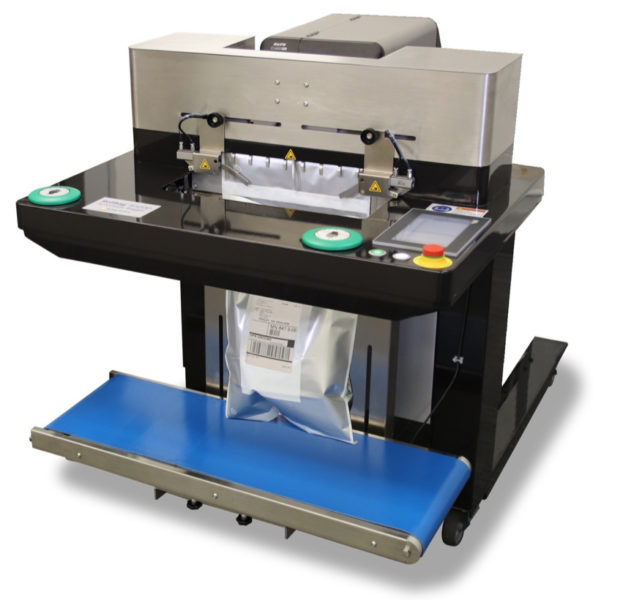

Auto Bag Mail Order Fulfilment Bagger

The Auto Bag mail order fulfilment bagger is a comprehensive system designed for efficient order fulfilment. This automatic bagger is compatible with both poly tubing and bags on a roll, providing versatility in packaging options.

Automated Packaging System

Equipped with a label printer applicator, the bagger provides a batch-less order fulfilment solution. It also has a thermal transfer printer option for direct printing on the bag material. A dual-sided label printer applicator is available to include shipping information and packing slip on a single label.

The order fulfilment bagger offers two label application methods: a direct thermal label applicator (no ribbon required) or a thermal transfer printer with ribbon. It comes in a base version for pre-made bags on a roll or fan-folded in a box and a version with poly tubing.

The benefits of poly tubing include lower material costs and right-sizing the bag to the product by changing bag length on the fly, lowering shipping costs, and reducing material usage.

Streamline Packaging Operations

This automated packaging system is ideal for e-commerce, order fulfilment and distribution facilities that require high-quality packaging operations. The roll bagging machine is available in two sizes to cater to different needs.

The standard model accommodates bags up to a maximum size of 12″ wide x 24″ long, with a seal bar opening of up to 6″. For larger bags, the larger version of the bagger can handle dimensions of up to 22″ wide x 46″ long, with a seal bar opening of up to 11″.

- Automated bagging for seamless order fulfilment

- Poly tubing compatibility for cost-effective bag sizing

- Integrated label printer applicator for efficient batch-less fulfilment

- Dual-sided label printer for simplified packaging information

- Versatile label application options: direct thermal or thermal transfer

- Configurable versions for different bag types

- Ideal for e-commerce and distribution facilities

- Two sizes available for flexible bag dimensions

- Cost and material efficiency with an adjustable bag length

- Streamlined packaging operations for enhanced efficiency

Auto Bag R3200 Standard

- Speed (Bags): Up to 40 bags/min

- Speed (Poly Tubing): Up to 20 bags/min

- Feed Rate: Up to 40”/sec

- Max Bag Width: 16”

- Max Bag Length: 24″

- Bag Thickness: 1–5 mil

- Electrical Requirement: 120V @ 20A

- Air Requirement: 80psi @ 5 CFM

- Warranty: 1 year, extendable up to 5 years

- Dimensions (W x D x H): 47” x 44” x 48”

Auto Bag R3200 XL

- Speed (Bags): Up to 40/min

- Speed (Poly Tubing): Up to 20/min

- Feed Rate: Up to 40”/sec

- Max Bag Width: 22”

- Max Bag Length: 36″

- Bag Thickness: 1–5 mil

- Electrical Requirement: 120V @ 20A

- Air Requirement: 80psi @ 5 CFM

- Warranty: 1 year, extendable up to 5 years

- Dimensions (W x D x H): 56″ x 60″ x 48″

Auto Bag R3200 Fulfilment Automatic Bagger Product Brochure - Humi Pak Malaysia: Download