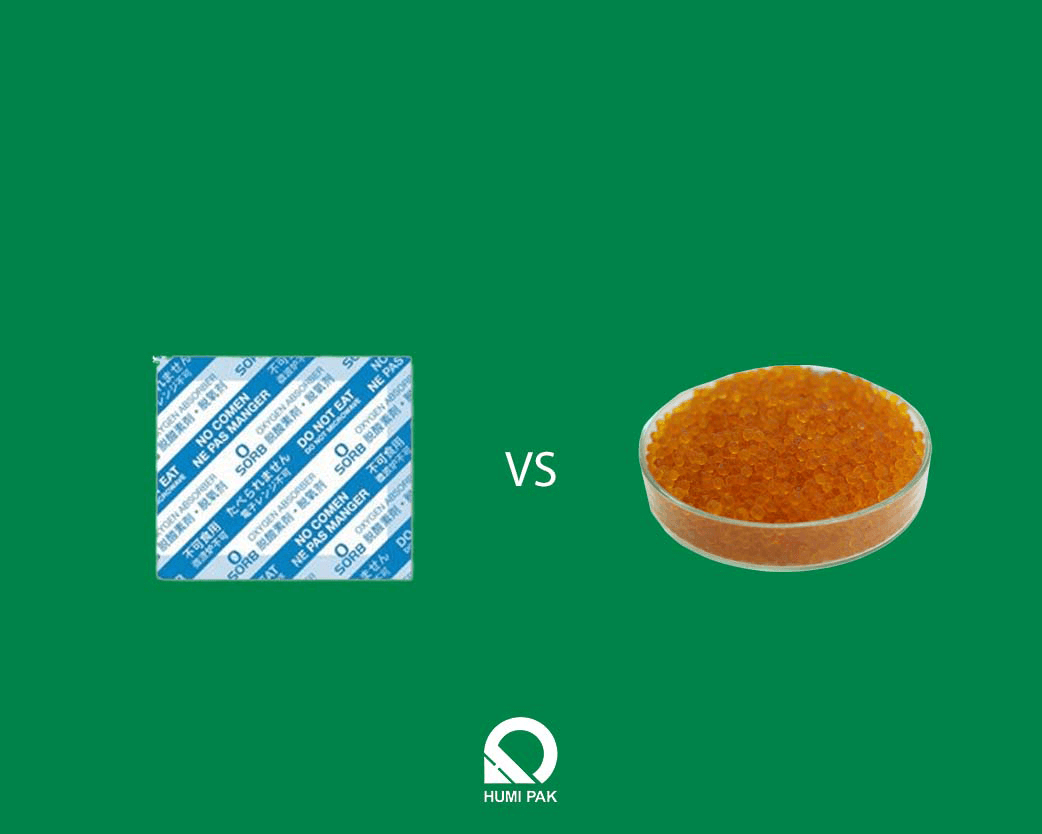

Oxygen Absorber vs Silica Gel : The Differences

Packaging, in its essence, safeguards products and preserves their quality. As the market evolves, so do the requirements and intricacies of packaging solutions. With the global reach of businesses, products now travel further, demanding packaging that withstands varying environments. From perishables to electronics, each product category has specific needs. Moreover, with growing environmental concerns, there’s an added emphasis on sustainability and reducing waste.

Moisture and oxygen, though ubiquitous, can be detrimental to many products. Excess moisture can compromise the integrity of goods, leading to mould formation or product malfunction. Similarly, oxygen exposure can cause food items to oxidize, affecting taste and nutritional value. Managing these two elements is important in preserving product quality, and that’s where solutions like oxygen absorbers and silica gels come in. As we explore these solutions, we’ll understand their roles, benefits, and applications in packaging.

What Are Oxygen Absorbers?

Oxygen absorbers are packets designed specifically to absorb oxygen, primarily used to ensure the shelf life and quality of various products by mitigating the harmful effects of oxygen exposure. The absorbers are small sachets filled with iron powder and salt. When exposed to oxygen, these components react and begin to rust, which draws oxygen from the surrounding environment into the sachet and out of the product’s packaging. Other materials, such as activated carbon or zeolite, may be added to enhance absorption capacity.

The working principle behind oxygen absorbers is the process of oxidation. When the iron powder inside the sachet comes into contact with oxygen, it forms iron oxide, commonly known as rust. This chemical reaction requires oxygen, so as the iron oxidizes, it actively pulls oxygen from the surrounding environment. The salt acts as a catalyst, speeding up this reaction, while other additives can help absorb residual moisture or gases. As a result, the internal environment of the package becomes notably depleted of oxygen, ensuring an anaerobic condition.

Common Applications and Uses:

Oxygen absorbers are versatile and find application in a range of industries:

- Food Packaging: They are most commonly found in the food industry, where they help prevent spoilage, maintain product freshness, and extend shelf life. They’re especially useful for products prone to spoilage from oxidation, such as dried fruits, nuts, and jerky.

- Pharmaceuticals: In the pharmaceutical industry, they ensure the efficacy and shelf life of medications by preventing oxidative degradation.

- Collectables and Valuables: For items like rare comics, artworks, and archival materials, oxygen absorbers can help prevent the yellowing and deterioration caused by oxidation.

- Electronics: The absorbers are sometimes used in packaging sensitive electronic equipment to prevent corrosion and maintain component integrity.

Benefits of Using Oxygen Absorbers

This small packet enhances numerous items’ shelf life and quality, particularly those sensitive to oxygen exposure. Oxygen absorbers ensure that when a consumer opens a package, whether it’s food or another type of product, it’s as close to its original quality as possible.

Enhanced Shelf-Life for Perishable Goods: Oxygen accelerates the degradation of many perishable items. By reducing its presence within sealed packages, the shelf life of these products is notably extended. This prevents rancidity in foods containing fats and oils and impedes the growth of microorganisms that thrive in oxygen-rich conditions. The result is longer-lasting freshness and a delay in spoilage.

Prevention of Mold, Mildew, and Spoilage: By introducing the absorbers into packaging, conditions become less favourable for these contaminants. This protective measure is especially crucial for organic and natural products. Similarly, the growth of aerobic bacteria, which can lead to spoilage, is substantially reduced. This defence mechanism benefits food items and non-food products, shielding them from potential damage and deterioration.

Maintaining Product Freshness and Quality: Foods, in particular, can have their flavours and fragrances altered with excessive oxygen exposure. Moreover, the vibrant colours of many products can fade due to oxidation. By regulating the internal conditions, these packets ensure products remain as fresh and appealing as intended. Furthermore, preserving essential nutrients, particularly those vulnerable to environmental factors, adds another benefit, ensuring consumers the nutritional content.

What Are Silica Gels?

Silica gel is a well-recognized desiccant, often encountered as small beads packed in porous pouches. Its primary function is to absorb moisture, ensuring a dry environment within the confines of a package. The desiccant is a form of silicon dioxide (SiO2) that is synthesized from sodium silicate. Its hard, crystalline structure and bead-like or granular appearance characterise it. The unique internal structure of the moisture absorber is highly porous, which allows it to absorb and hold water vapour effectively.

The effectiveness of silica gel as a desiccant lies in its physical properties. The large surface area within its porous structure provides ample space for water molecules to adhere. When exposed to a humid environment, water vapour from the surrounding air is drawn into the pores of the silica gel beads. This process is primarily physical absorption, where water molecules adhere to the surface of the beads due to van der Waals forces. As the silica gel becomes saturated with moisture, its efficiency decreases, but heating can regenerate it to release the trapped water, restoring its desiccant properties.

Applications in Packaging:

Silica gel’s moisture-absorbing properties make it suitable for various packaging requirements in protecting products from the effects of moisture.

- Electronics: Silica gel packets are often found in electronics packaging to prevent moisture-induced damage and corrosion to sensitive components.

- Food Products: While not as common as oxygen absorbers in food packaging, the desiccant can prevent clumping in powdered foods or maintain the dryness of certain dried goods.

- Pharmaceuticals: To ensure medications and pills remain dry and effective, silica gel sachets are sometimes included in pharmaceutical packaging.

- Leather Goods and Textiles: Products susceptible to mould and mildew growth, like leather shoes or bags, may come packaged with the desiccant to absorb ambient moisture.

- Shipping and Storage: Silica gel can be used in larger quantities in shipping containers or storage boxes to regulate humidity and prevent damage to goods during transport or prolonged storage.

Advantages of Silica Gel in Packaging

Integrating silica gel into packaging strategies offers a blend of moisture control, sustainability, and adaptability.

Effective Moisture Control: The porous nature of the gel allows it to attract and trap water molecules, ensuring that the environment within a package remains largely moisture-free. This is crucial for many products, as excess humidity can lead to spoilage, damage, or reduced efficacy. By absorbing unwanted moisture, silica gel preserves the integrity of products, ensuring they reach consumers in optimal condition.

Reusability Options: When the gel has reached its moisture-absorbing limit, it can often be regenerated through heating, allowing it to be used multiple times. This attribute offers cost-saving benefits and contributes to a reduced environmental impact, as it minimizes waste.

Versatility in Various Industries:Its role is pivotal in the electronics sector, preventing moisture-related damage to sensitive components. The food industry keeps products like powdered items free from clumping due to humidity. The pharmaceutical realm relies on it to maintain the efficacy of drugs by staving off moisture-driven degradation. Leather and textile sectors benefit from its ability to ward off mold and mildew. Even in logistics, during shipping or storage, silica gel ensures products remain in good condition,

Differences Between Oxygen Absorbers and Silica Gel

While oxygen absorbers and silica gel play critical roles in product preservation, their functionalities, durability, limitations, and costs make them suitable for different applications.

Functional Differences: Oxygen vs. Moisture Removal

- Oxygen Absorbers: These are designed to remove oxygen from their environment. By doing so, they help prevent product oxidation, inhibit aerobic bacteria growth, and extend perishable items’ shelf life.

- Silica Gel: This desiccant primarily targets moisture. Its primary role is to absorb water vapour from the surrounding environment, reducing the relative humidity within packages. This is particularly useful for moisture-sensitive products, as it prevents condensation, mould growth, and other moisture-related damages.

Durability and Lifespan

- Oxygen Absorbers: Their functionality is based on a chemical reaction. Once all the reactive components in the absorber have been utilized, its lifespan ends. They are single-use items and cannot be regenerated for reuse.

- Silica Gel: It boasts a longer lifespan due to its physical mode of moisture absorption. When saturated, silica gel can often be regenerated by heating and reused, making it more durable.

Potential Risks and Limitations

- Oxygen Absorbers: Their main limitation is that they target only oxygen. They don’t protect against moisture. Overusing them can sometimes create a vacuum in packaging, causing it to collapse if not adequately structured.

- Silica Gel: While efficient at removing moisture, it does not address the oxygen content, which can be a limiting factor for products prone to oxidation. Additionally, if silica beads are ingested, they can pose a health risk, so they often come with a “Do Not Eat” warning.

Cost Implications

- Oxygen Absorbers: Typically, these costs are influenced by their oxygen-absorbing capacity. Depending on the product’s requirements and the packaging volume, their expense can vary. They might be more cost-effective for items where oxygen control is the primary concern.

- Silica Gel: The cost can be mitigated by its reusability feature. However, initial investments might be higher than oxygen absorbers, especially for specialized or indicating gels that change colour upon saturation.

Comparison Chart: Oxygen Absorbers vs. Silica Gel

| Feature/Aspect | Oxygen Absorbers | Silica Gel |

|---|---|---|

| Primary Function | Oxygen removal | Moisture removal |

| Durability/Lifespan | Single-use (non-regenerable) | It can be regenerated and reused |

| Risks & Limitations | – Targets only oxygen<br>- Potential vacuum in packaging | – Doesn’t address oxygen content<br>- Ingestion hazard |

| Cost Implications | Costs vary by capacity; it may be more cost-effective for oxygen control | Initial costs might be higher, mitigated by reusability |

| Material Composition | Often contain iron powder | Made from silicon dioxide |

| Indication of Saturation | No direct indication; often rely on package condition | Some types change colour when saturated |

| Environmental Considerations | Non-biodegradable; require proper disposal | Reusable nature may reduce environmental impact |

| Common Applications | Food preservation, pharmaceuticals | Electronics, pharmaceuticals, food, leather goods |

Safety and Environmental Considerations

Proper disposal, awareness of potential hazards, and understanding of their environmental footprint can lead to more responsible and sustainable usage.

Disposal and Recycling Options

- Oxygen Absorbers: Most oxygen absorbers are non-biodegradable due to their composition, often containing elements like iron powder. While the iron can degrade over time, the outer packaging can persist. Recycling options are limited. It’s essential to consult local waste management policies, but in most cases, they are disposed of in general waste.

- Silica Gel: Depending on local recycling guidelines, Silica gel packets can sometimes be recycled. The gel, made from silicon dioxide, is non-toxic and can degrade over time. However, the packets holding the gel often require disposal in general waste. Given their regenerative properties, an eco-friendly approach is to reuse silica gel packets.

Safety Precautions for Consumers

- Oxygen Absorbers: While the components inside these absorbers are not typically toxic, they shouldn’t be consumed. They pose a choking hazard, especially to children. Moreover, if the packet ruptures, the contents can stain or damage the product it’s protecting.

- Silica Gel: The most common safety warning of silica gel packets is “Do Not Eat.” While the gel itself is non-toxic, it can be a choking hazard. Some silica gels are also treated with colour-changing indicators to show saturation; these may contain cobalt chloride, which is toxic and shouldn’t be ingested.

Environmental Impact

- Oxygen Absorbers: Their single-use nature means a higher turnover of waste. The iron powder inside can rust and degrade, returning to the environment. However, the packets can contribute to environmental waste, especially if disposed of incorrectly.

- Silica Gel: The primary environmental advantage of silica gel is its reusability. When regenerated and reused, it reduces the need for producing more packets, thereby minimizing waste. However, like oxygen absorbers, the outer packet material can have a lasting environmental impact if not properly disposed of or recycled.

Making the Choice: When to Use Which

Choosing between oxygen absorbers and silica gel hinges primarily on the needs of the preserved product. If the primary concern is the oxidation of the product, such as in the case of certain foods or metals, oxygen absorbers are typically the go-to. On the other hand, for products sensitive to moisture, like electronics or textiles, silica gel might be the better choice.

Another significant consideration is the structure and size of the packaging. Using too many oxygen absorbers might result in a vacuum effect in certain packaging types, while silica gel’s weight and volume might be restrictive for others. Cost is also a pivotal factor in making a decision. Silica gel, while reusable, might have higher initial costs compared to oxygen absorbers.

By considering the specific needs and risks associated with a product, one can decide whether to opt for oxygen absorbers or silica gel. Both serve unique roles and understanding their strengths can lead to optimal product preservation. Humi Pak is a packaging supplier specializing in silica gel and oxygen absorbers.

Our oxygen absorbers are made to meet the quality standards using advanced Japanese technology and materials. Moreover, our silica gel packets are manufactured in Malaysia, adhering to ISO 9001 and 14001 certifications. To discover how to protect your goods from damage best, schedule an appointment with our packaging engineers, and let us help you through tailored solutions for your needs.